Welcome to Modulus Metal, a leading manufacturer of high-quality stainless steel investment casting products based in Turkey. Our state-of-the-art facilities and skilled workforce allow us to produce precision castings for a wide range of industries and applications using investment casting process. We are proud to export our products to countries such as the USA, Canada, Germany, France and many other countries.

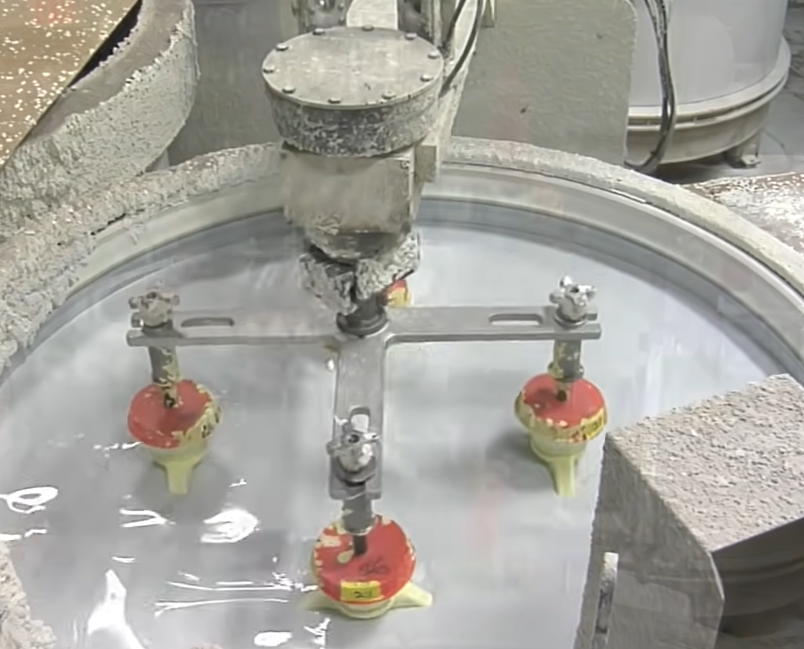

Investment casting is a precision casting process that involves making a wax pattern of the desired shape, coating it with a refractory material, and then heating it to melt the wax and form a ceramic mold. The molten stainless steel is then poured into the mold and allowed to cool and solidify. Once cooled, the ceramic mold is broken away, revealing the cast stainless steel component.

One of the key advantages of using stainless steel in investment casting is its excellent corrosion resistance, which makes it suitable for use in a wide range of applications, particularly in harsh environments. Stainless steel is also known for its high strength and durability, making it ideal for use in components that will be subject to high loads or wear. Additionally, stainless steel investment casting can produce highly complex and intricate shapes with a high degree of accuracy and consistency, which makes it ideal for use in precision components and equipment.

We use a variety of different types of stainless steel in our investment casting process, including:

- Austenitic stainless steel: This type of stainless steel is the most commonly used in investment casting. It is characterized by its excellent corrosion resistance, high toughness, and ease of fabrication. Examples of austenitic stainless steels include AISI 304 (ASTM 304, ASME SA312), AISI 316 (ASTM 316, ASME SA312, DIN 1.4401, BSI 316S11)

- Martensitic stainless steel: This type of stainless steel is known for its high strength and hardness. It is often used in investment casting applications that require high strength and wear resistance, such as gears and pump parts. Examples of martensitic stainless steels include AISI 410 (ASTM 410, ASME SA276, DIN 1.4006, BSI 410S21) and AISI 420 (ASTM 420, ASME SA276, DIN 1.4021, BSI 420S37)

- Ferritic stainless steel: This type of stainless steel is characterized by its excellent corrosion resistance and good thermal stability. It is often used in investment casting applications that require high-temperature resistance and low thermal expansion. Examples of ferritic stainless steels include AISI 430 (ASTM 430, ASME SA268, DIN 1.4016, BSI 430S15) and AISI 446 (ASTM 446, ASME SA268, DIN 1.4762, BSI 446S19)

Our stainless steel investment castings are used in a variety of industries, including:

- Aerospace

- Medical Devices

- Food Processing

- Automotive

- Agriculture

- Petroleum & chemical

- Marine

- Power Generation

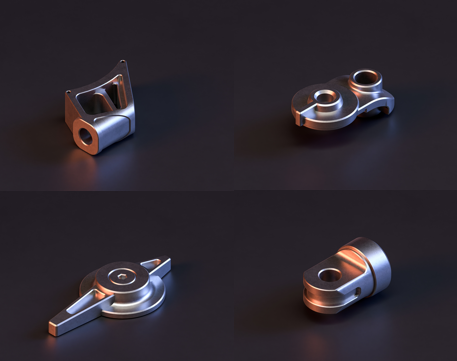

Some examples of the components we manufacture using stainless steel investment casting include:

- Valve bodies

- Impellers

- Turbine blades

- Bearings

- Pump housings

- Gearboxes

- Pipe fittings

- Firearm components

- Medical devices and equipment

At Modulus Metal, we are dedicated to providing our customers with the highest-quality investment castings. Our strict quality control processes ensure that each and every one of our castings meets the most demanding industry standards and the standards like AISI, ASTM, ASME, DIN, BSI etc. Our differences are project management capabilities, experienced in export, foreign customer requirements, easy to communication, high skilled experienced engineers, always available to give prompt feedbacks. Our experienced engineers are well-versed in export regulations and requirements, and are able to work closely with our clients to ensure that their specific needs are met. We are committed to providing prompt and responsive customer service, and are always available to give feedbacks to clients on their projects. Contact us today to learn more about how we can meet your stainless steel investment