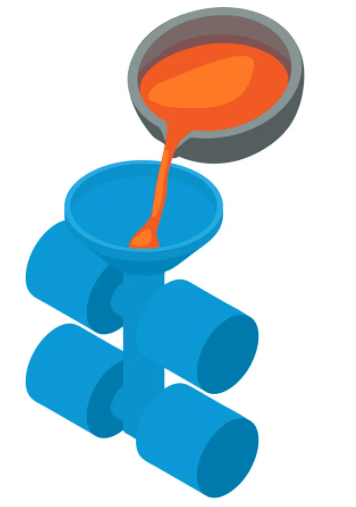

Investment casting, also known as a lost wax casting, is a manufacturing process that involves creating a mold of a desired part using a wax or polymer pattern. The mold is then coated with a ceramic material and heated to high temperatures to melt or burn out the wax pattern, leaving a hollow cavity in the shape of the final part. Molten metal is then poured into the cavity and allowed to cool and solidify. Once the metal has hardened, the ceramic mold is broken away to reveal the finished investment casting.

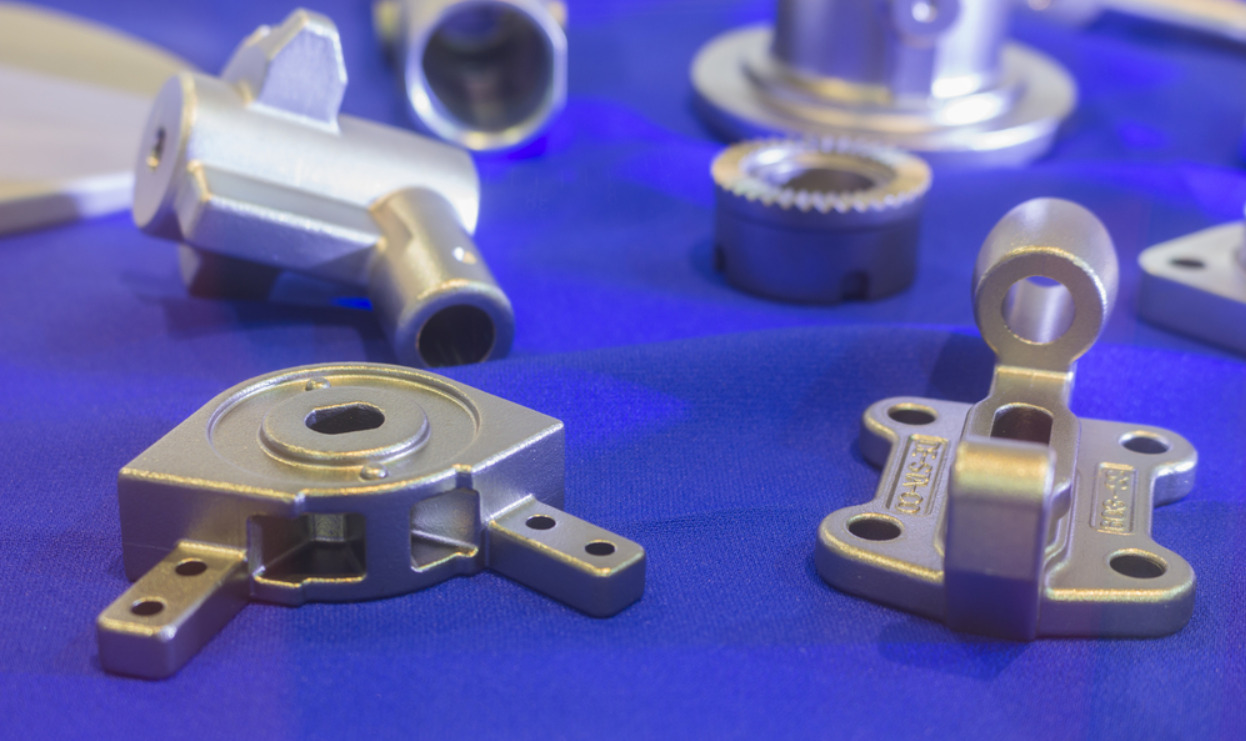

Investment casting is a popular choice for manufacturing parts for a variety of industries, including aerospace, military, medical, and automotive. It allows for the production of complex shapes and fine detail that may not be achievable with other casting methods. It also allows for the use of a wide range of materials, including steel, aluminum, and superalloys.

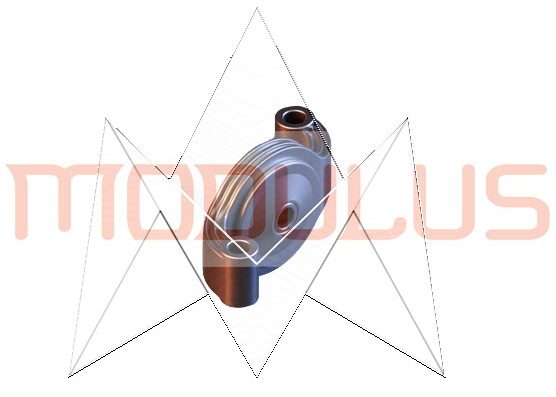

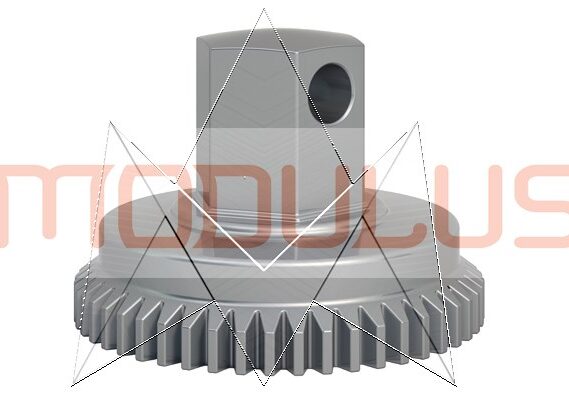

Modulus Metal is a leading manufacturer of investment casting parts, with state-of-the-art facilities and a team of experienced professionals. We use advanced techniques and the latest technology to produce high-quality, precise investment castings for a variety of applications. Contact us today to learn more about how investment casting can benefit your business.

Modulus Metal has ISO / IATF-certified investment casting supplier base and our partner suppliers are experienced in automotive, aerospace, agricultural, biomedical and industrial machinery manufacturing for many years.

Production capabilities: 1g to 50 kg /piece

Quantity: Medium to large volumes of production

STANDARD INVESTMENT CASTING

The method

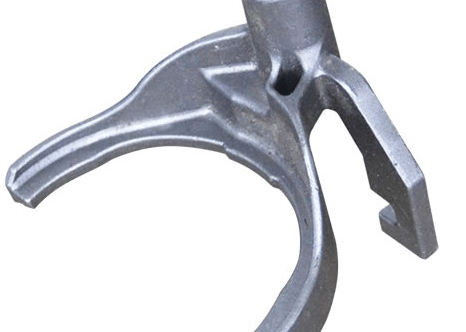

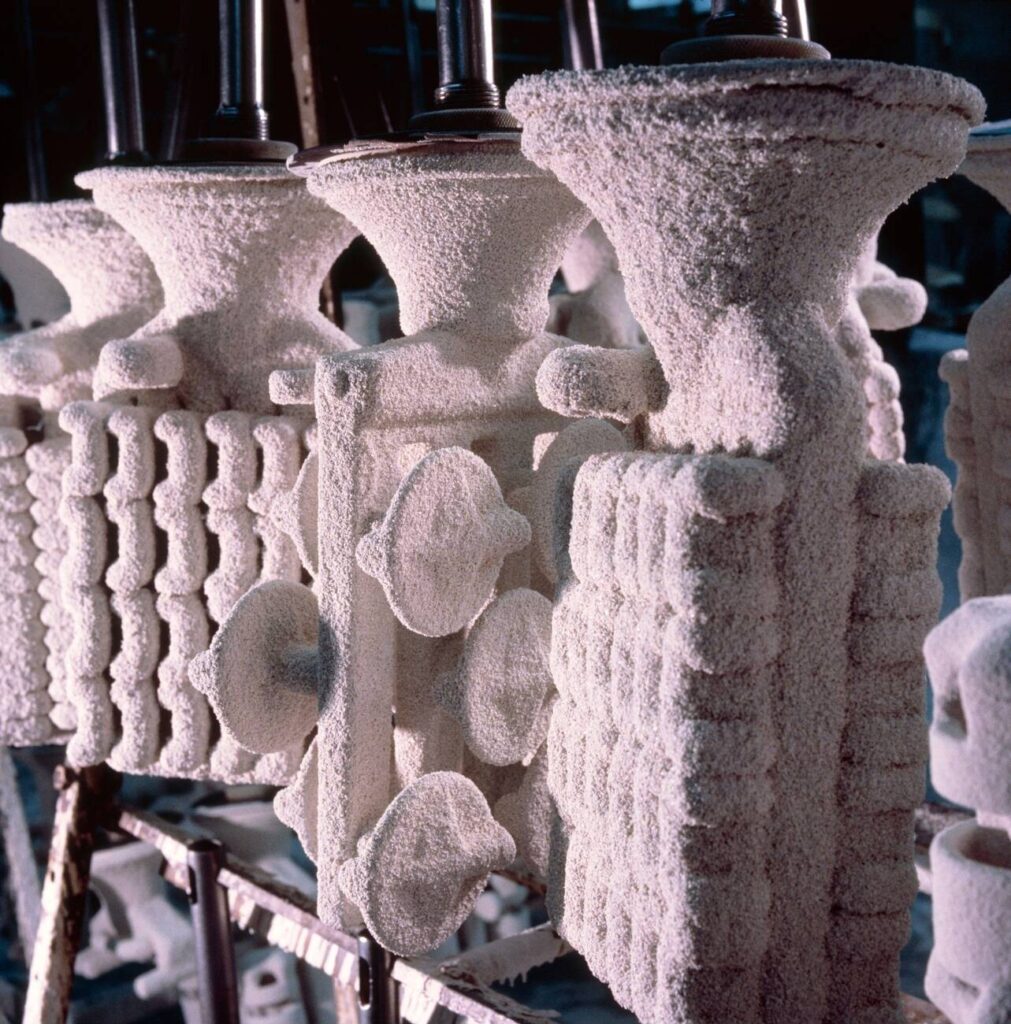

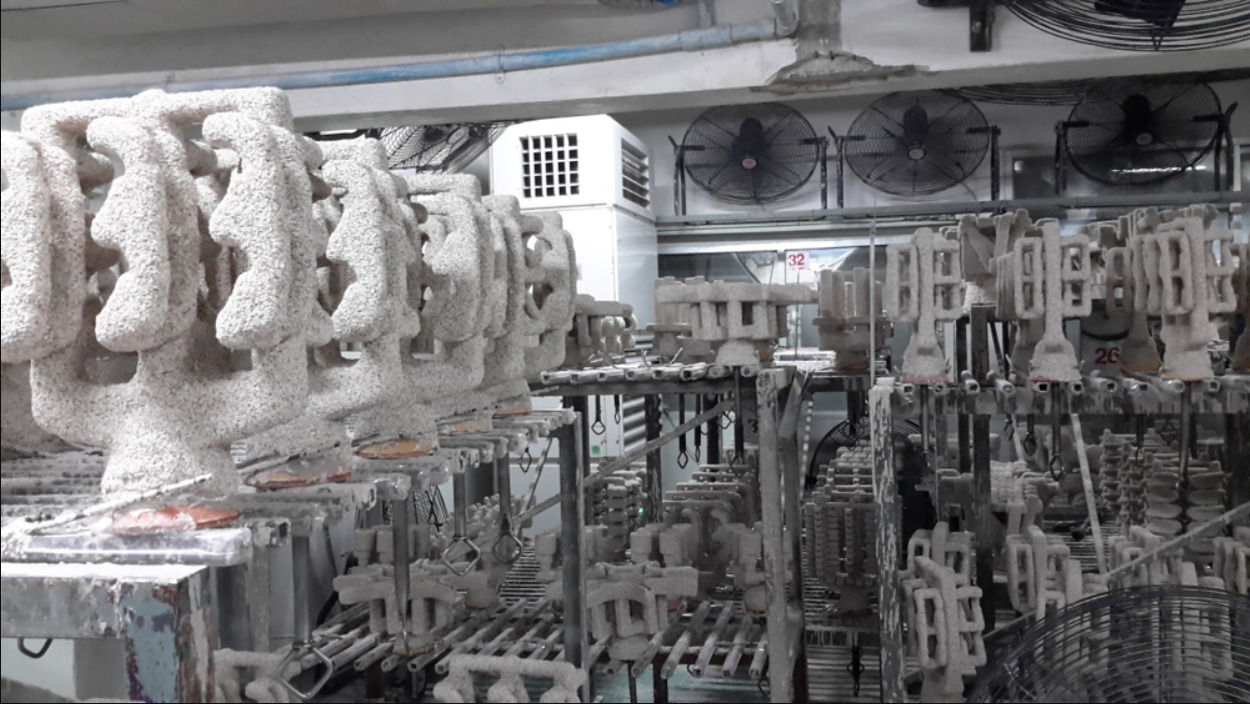

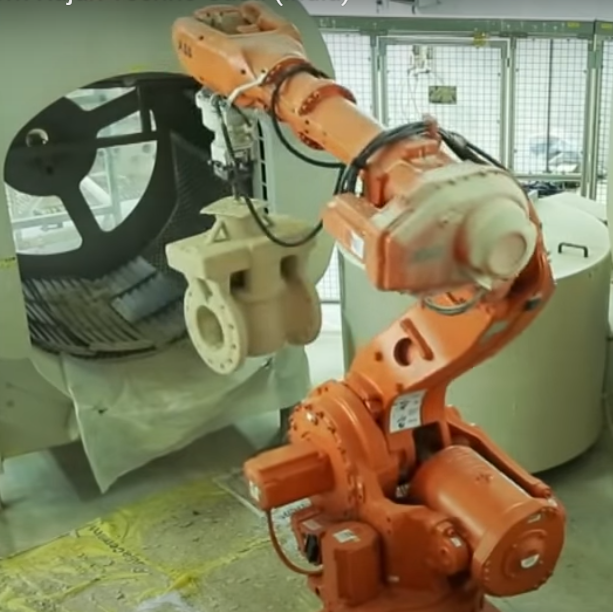

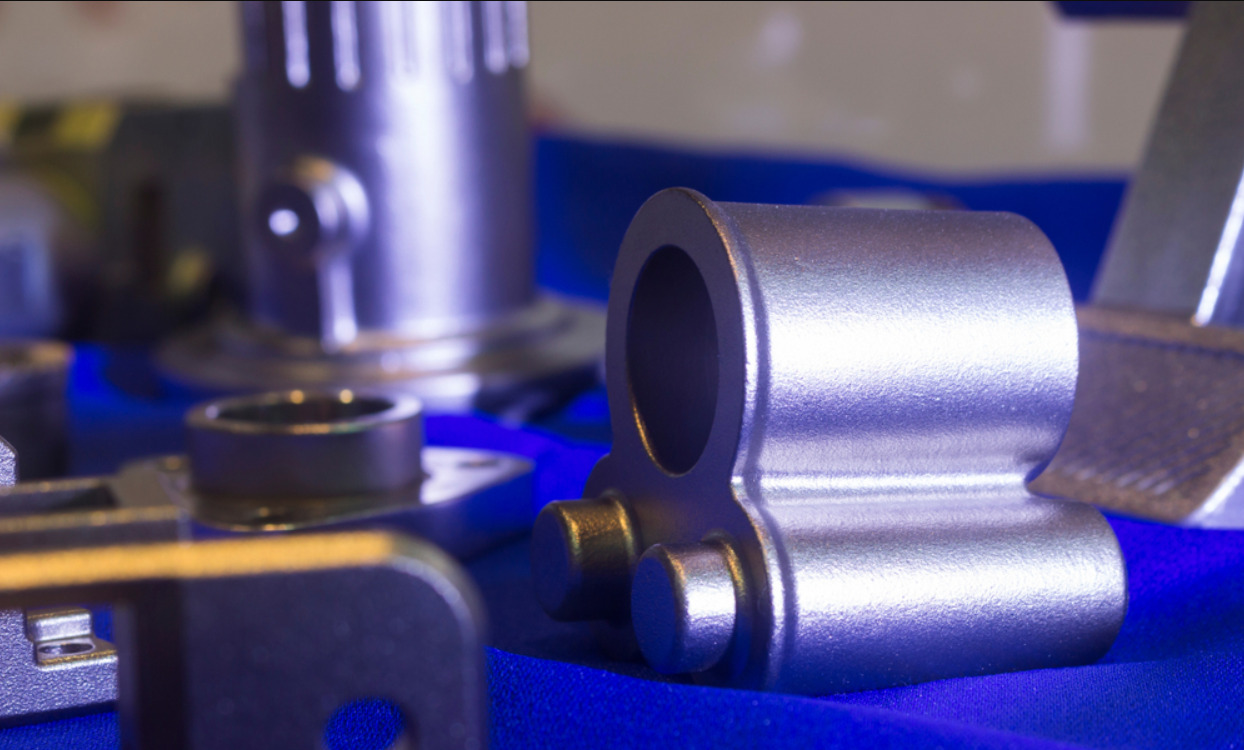

Wax patterns are created in INVESTMENT CASTING and then built on a tree with feeding and gating systems. The wax pattern is dipped in refractory slurry, then covered in refractory stucco and left to dry for many hours. This is the initial coat. The method is done several times, usually until 8 coats of refractory are obtained. The ceramic investment shell is shown here. The wax is then melted out and the ceramic shell is baked before the molten metal is cast into it. When intricate, thin portions are involved, air pressure, vacuum, or centrifugal pressure might be used to assure complete filling of the mold. To remove the castings, the mold is broken up. Most metals with melting temperatures less than 2500°K (2227°C) can be processed using this method. Because the wax pattern is melted out, structures with curves, undercuts, bosses, recesses, and so on can be quite complicated. The Lost Wax Process is another name for it.

Process characteristics : Primary shaping process , Discrete

Design guidelines

Complex shapes featuring curves, undercuts, bosses, recesses, and so on. Ideal for compact three-dimensional shapes.

Technical information

Cycle time limited by heat transfer out of casting.. The use of several molds boosted the production rate. The method provides great detail replication.

Typical uses

Small complex automotive and industrial parts, Jewelry, dental implants, statuary, metal sculpting, and decorative objects are common applications.

Other Types of Investment Casting Modulus Metal serves:

- CLA / CLV

- Replicast

- Vacuum Investment Casting

Standard References: