Modulus Metal is a company that provides heat treatment services to improve the mechanical properties of various materials, including steel. Our team of experts is trained in various heat treatment techniques, including stress relieving.

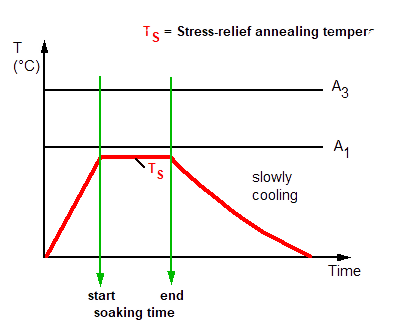

Stress relieving is a process that is used to reduce the internal stresses that can be present in a material after it has been subjected to mechanical deformation or machining. Stress relieving involves heating the material to a temperature below its critical temperature (the temperature at which the material’s microstructure changes), holding it at that temperature for a period of time, and then slowly cooling it. This process helps to relax the internal stresses in the material, which can improve its mechanical properties, such as its strength and ductility.

Stress relieving is often used for steel parts that have been subjected to high levels of deformation or machining, as it can help to improve the dimensional stability and fatigue strength of the parts. It is also often used as a final heat treatment step after other heat treatment processes, such as quenching and tempering, to further improve the mechanical properties of the parts.

Modulus Metal is committed to helping its clients improve the mechanical properties of their materials through heat treatment. Contact us today to learn more about our stress-relieving services and how we can help you achieve the desired properties for your materials.