Modulus Metal has ISO & IRIS certified supplier base and our partner suppliers are experienced in automotive, aerospace, agricultural, railway, and industrial machinery manufacturing for many years.

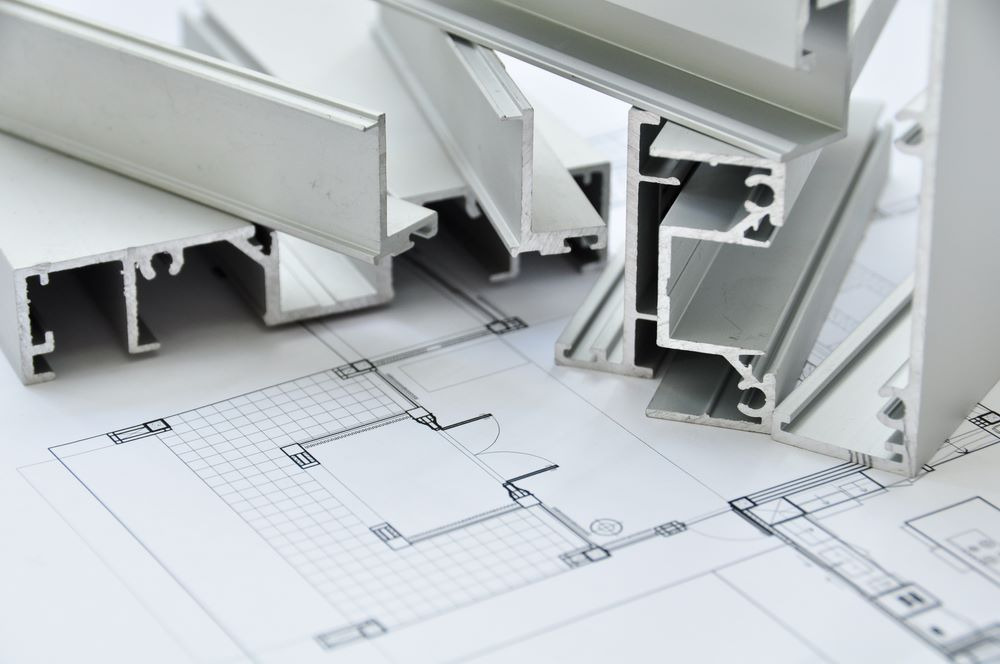

HOT METAL EXTRUSION

The Method

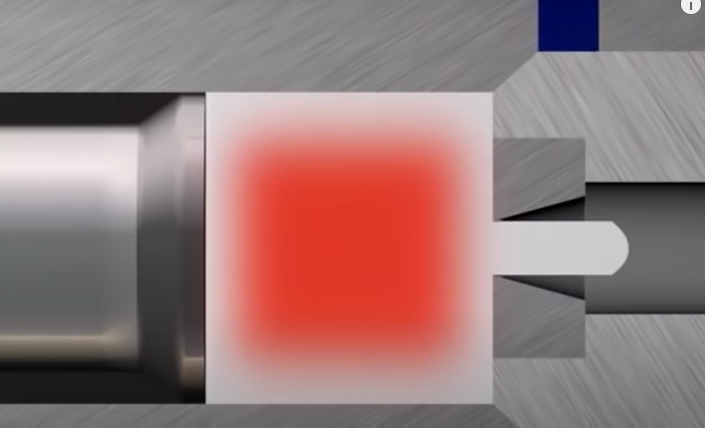

A compressive force is applied to a metal billet to push it to flow through a shaped die. There are two methods: direct extrusion and indirect extrusion

Direct Extrusion: Stationary Die

Indirect Extrusion: Stationary Billet

The benefit of indirect extrusion is that there is less friction between the billet and the container, which results in reduced extrusion forces; nevertheless, the equipment is more complex, and the product length is limited.

Hot extrusion is only possible with ductile metals with room temperature hardnesses less than 6 GPa and melting points less than 1727°C. Brittle materials can be extruded with a hydrostatic extrusion

Process characteristics : Primary Shaping Process , Continuous

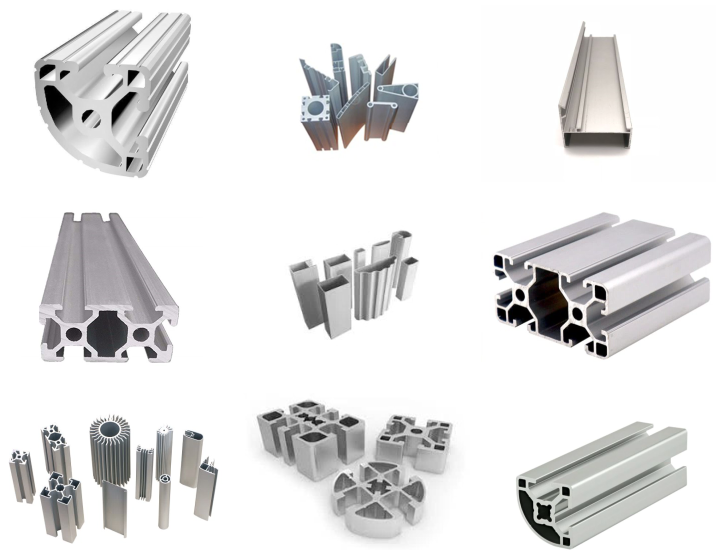

Design principles : Limited to shapes of constant cross section

Technical information

Extruded metals: Aluminum and aluminum alloys, copper and copper alloys, magnesium, low-carbon and medium-carbon steels, low-alloy steels, and stainless steels are the most prevalent.

Typical applications

A wide range of components are available, including tubing, window frames, construction and vehicle trim, aviation structural parts, railings, and so on.

IMPACT EXTRUSION (COLD EXTRUSION)

The Method

IMPACT EXTRUSION is a cold extrusion method that combines forging and extrusion principles to produce completed or almost completed products.

Backward or forward extrusion, or a mixture of the two, can be used to manufacture components (combined extrusion). Backward extrusion involves inserting a blank into a die chamber and striking it with a punch to extrude it upward. The space between the punch and the die chamber determines the thickness of the extruded tubular segment. The blank is put in the die cavity during forward extrusion, and the punch compresses it and causes it to flow through the die aperture.

Forward extrusion is often utilized to fabricate solid rod and tube forms, whereas backward extrusion is utilized to create hollow shells with closed ends.

Process characteristics : Primary Shaping Process , Discrete

Design principles : Ideal for symmetrical forms. Particularly suitable for round, hollow, shells with one end closed, and solid rod and tube forms.

Technical information

Aluminum, copper, lead, magnesium, tin, zinc alloys, and carbon and low alloy steels are all often utilized.

Typical applications

Aluminum gas bottles, aerosol cans, fire extinguishers, shaving cream and toothpaste collapsible tubes, and soft drink cans

Other Types of Extrusion Processing method Modulus Metal serves:

Ceramic Extrusion