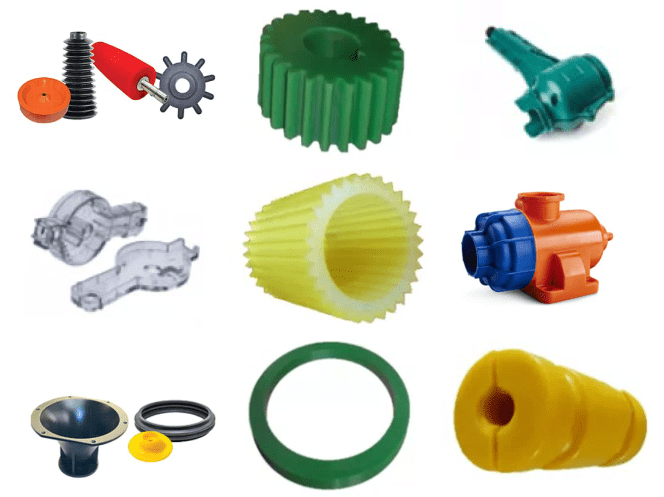

CASTING

The act of pouring liquid polymeric material into a mold is known as casting. The mold has a hollow hole that is the correct size and form. To create the solid, the material that was molded is allowed to cool. Casting is the solidified component that is forced out of the mold to complete the process. Three main categories of casting processes are recognized:

- Die casting

- Rotational casting

- Film casting

Die Casting:

Die casting is a typically low-cost method that produces items in the desired shape and size out of liquid pre-polymer. This technology can be used to make sheets, tubes, and rods.

The pre-polymerized substance is placed into a petridish along with a creative and other element. The polymeric substance is then cured by keeping the petridish in an oven at a high temperature. The solid result from the petridish is extracted after cooling to room temperature. Thus, the solid’s shape is exactly like that of the petridish’s inside. We utilize a cylindrical die for products with a cylindrical shape.

Up until the formation of the solid product, polymerization is permitted to continue inside the die.

Die casting is a good use for polymeric materials such as polyester, epoxies, acrylics, and polyurethanes. The die for casting might be made of glass, lead, or plaster depending on convenience and availability.

Rotational Casting

Hollow objects like balls, dolls, and rain boots are made using rotational casting.

The hollow mold is filled with the composited thermoplastic materials in the form of a fine powder. The option exists to concurrently rotate the mold along the primary and secondary axes. The mold is heated and turned after being cast. Through this procedure, the molten plastic is evenly distributed around the interior cavity of the mold. The mold is eventually cooled with cold water while being rotated. The plastic material within the cavity cools and hardens as a result, taking on the form of that surface. Now that the mold has opened, the product is taken out. A thermosetting type polymer and inventive mixture can also be employed as an alternative to thermoplastic materials, with the curing process taking place at a high temperature while rotating.

Film Casting

A polymer sheet is made possible via the film casting process. In the process, the polymer solution is allowed to fall at a specific rate on an infinite metallic belt while being stirred at a consistent pace. As a result, a film of the polymeric solution is stretched across the metallic belt. The solvent evaporates at the metallic belt, turning the polymer into a tough sheet.