Friction Welding of Metals

In friction welding, two components are brought into close proximity by being rotated or vibrated swiftly. This causes frictional heat to build up at the interface, and when it does, the two components are welded together. Direct drive friction welding uses a connected motor that begins and stops with each operation while being connected to the work piece.

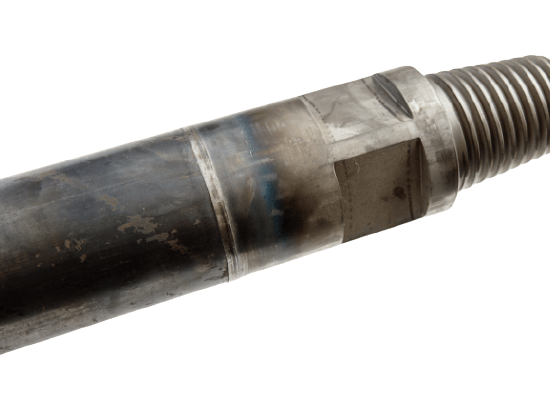

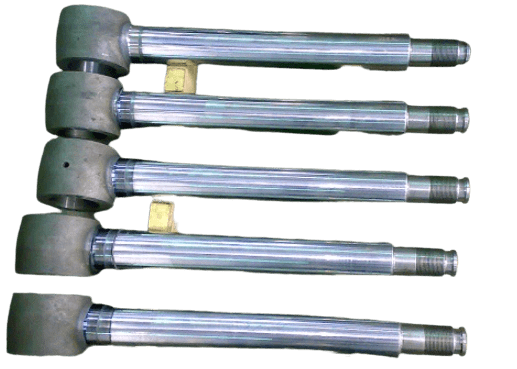

In inertial friction welding, a fly wheel that is not linked to the motor is driven by the motor to create the weld. A non-consumable rotating tool is pushed onto the materials to be fused in friction stir welding. The two pieces being joined are compressed between the central pin and shoulder, which heats and plasticizes the materials. Material from the tool’s front is swept around to its back as it advances along the joint line, removing the interface. The procedure is eco-friendly, and the weld quality is high (equal to the best fusion welds).

Friction-Stir Welding

A non-consumable rotating tool is pushed onto the materials to be fused in friction stir welding. The two pieces being joined are compressed between the central pin and shoulder, which heats and plasticizes the materials. Material from the tool’s front is swept around to its back as it advances along the joint line, removing the interface.

The procedure is environmentally benign, and the weld quality is outstanding. Because there is no melting, the volume changes brought on by solidification are prevented, and residual stress and distortion are minimal. Currently, the method is used to weld aluminum and magnesium alloys, but advancements are anticipated that will enable welding of copper, titanium, and steel. Joints between different metals, such as Mg alloys and Al alloys, are useful.