Work With Expert

We are a service company specializing in the PPAP CONTROL AND PART APPROVAL PROCESS. Modulus Metal is your address for prototype and pre-serial steps through Consulting. We examine your parts and PPAP documents to help you during the approval process.

PPAP, or Production Part Approval Process, is a standardized process used in the automotive industry to ensure that parts and assemblies meet the customer’s specifications and requirements. The PPAP process involves submitting a package of documentation to the customer for review and approval.

The PPAP package includes a variety of documents, including:

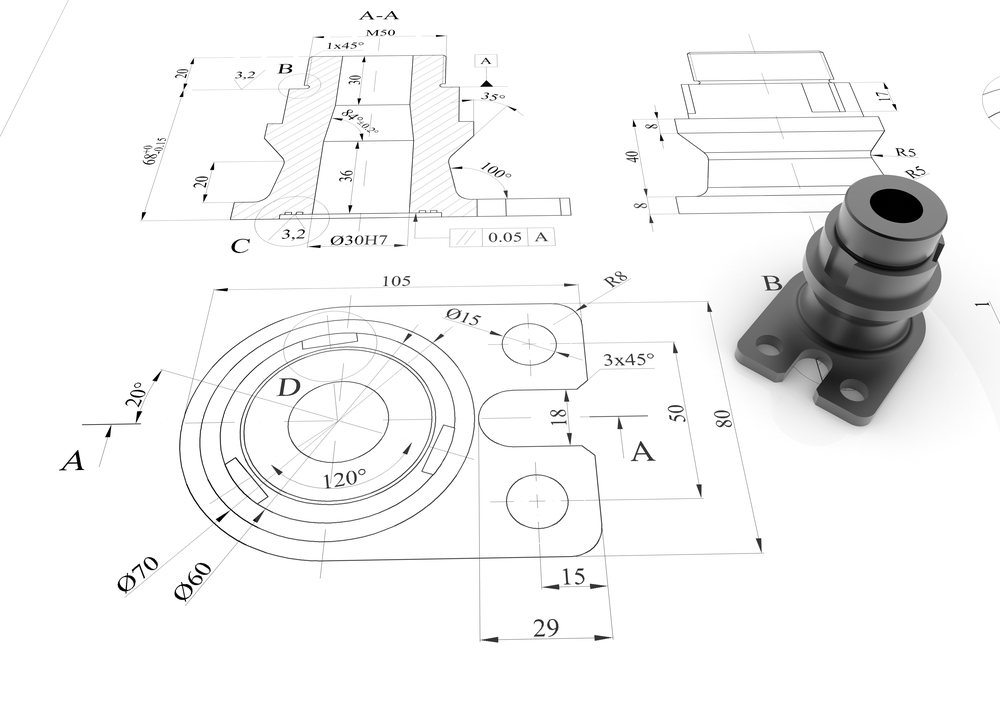

- Design records: drawings, specifications, and other documents that describe the part or assembly

- Process flow diagrams: a visual representation of the steps involved in the production process

- Process failure mode and effects analysis: a systematic approach to identifying potential failure modes in a process and determining their potential effects on the end product

- Control plan: a document that outlines the controls that will be put in place to ensure that the product meets the customer’s specifications and requirements

- First article inspection report: a report that documents the results of the initial inspection of a new product or process

- Other documents as required by the customer

PPAP Levels:

PPAP LEVEL 1: This is the most basic level of PPAP and is typically used for low-volume or low-complexity parts. The PPAP package for Level 1 includes:

A design record

A process flow diagram

A control plan

PPAP LEVEL 2: This level is typically used for parts that are of moderate complexity or that have some level of design changes. In addition to the documents required for Level 1, the PPAP package for Level 2 includes:

A process failure mode and effects analysis

A first-article inspection report

PPAP LEVEL 3: This level is typically used for high-volume or high-complexity parts. In addition to the documents required for Levels 1 and 2, the PPAP package for Level 3 includes:

Samples of the part or assembly

Process and inspection records

A master sample

A check sheet for measurements

PPAP LEVEL 4: This is the highest level of PPAP and is typically used for parts that are critical to the safety or performance of the end product. In addition to the documents required for Levels 1, 2, and 3, the PPAP package for Level 4 includes:

Evidence of process capability

Evidence of performance testing

PPAP Documents:

- Design Records

– For proprietary components/details

– for all other components/details - Engineering Change Documentations, if any

- Customer Engineering approval, if required

- Design Failure Mode and Effect Analysis (DFMEA)

- Process Flow Diagrams

- Process Failure Mode and Effect Analysis (PFMEA)

- Control Plan

- Measurement System Analysis Studies

- Dimensional Results

- Material, Performance Test Results

- Initial Process Studies

- Qualified Laboratory Documentation

- Appearance Approval Report (AAR), if applicable

- Sample Product

- Master Sample

- Checking Aids

- Records of Compliance with Customer-Specific Requirements

- Part Submission Warrant (PSW)

Standards: IATF 16949, AS9145, ISO 9001

At Modulus Metal, we have the experience and expertise to assist you with the PPAP CONTROL AND PART APPROVAL PROCESS. Whether you are a supplier or a manufacturer, we can help you navigate the process and ensure that your parts and assemblies meet the customer’s requirements.

Thank you for considering Modulus Metal for your PPAP needs. If you have any questions or would like to discuss your project in more detail, please don’t hesitate to contact us.