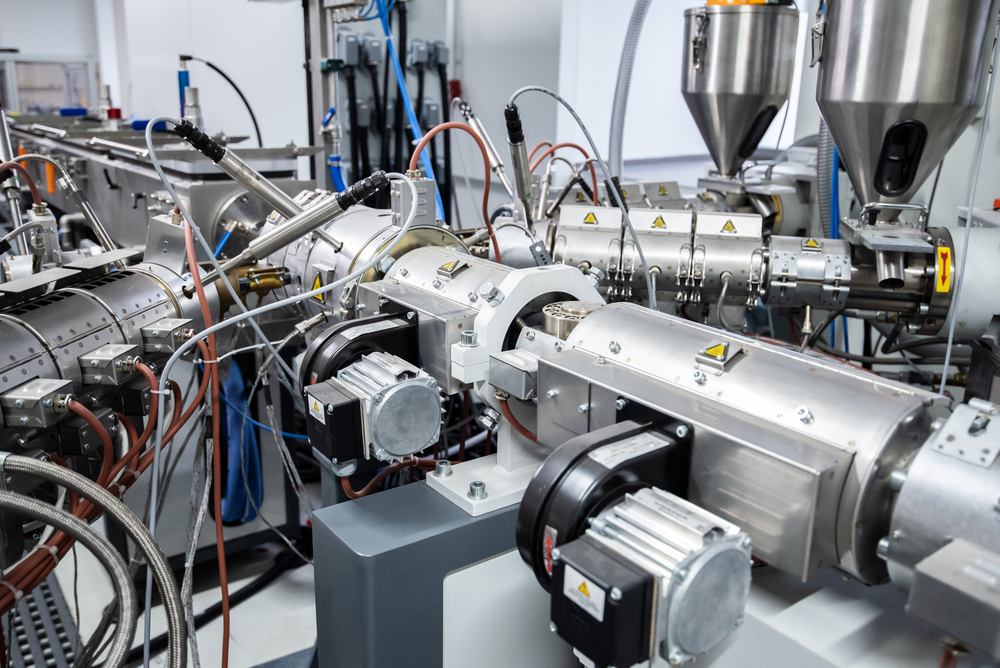

In polymer extrusion, a revolving screw processes polymer in powder or granule/pellet form via a heating chamber before forcing the resulting melt through a formed die opening.

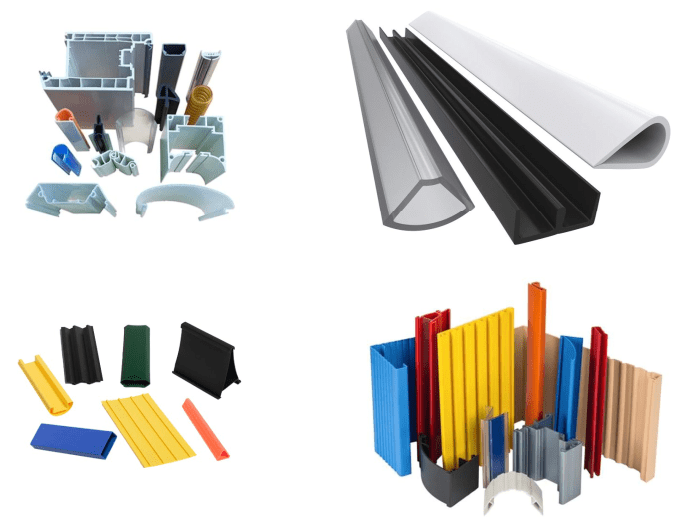

As the extrudate emerges from the die, it cools. A smaller cross-section of the extrudate is then “pulled down” from it. Film blowing, extrusion blow molding, and filament forming are examples of process variations.

The procedure is used to coat wire, and it may be done quickly. Many molding methods, including injection molding, require extrusion as a preliminary step.

Although capital costs are significant and the result typically requires additional processing, from simple cutting to size to remelting and injection molding, the technique has the advantage of having comparatively low tooling costs. Because “die swell” complicates die design, tolerances are looser than for pressure molding procedures.