Modulus Metal has ISO & IATF-certified sheet metal parts production suppliers and our partner suppliers are experienced in automotive, aerospace, agricultural, and industrial machinery manufacturing for many years.

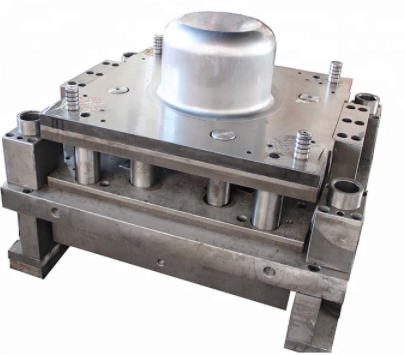

DEEP DRAWING

The Method

DEEP DRAWING is the process of converting a flat sheet-metal blank into a cylindrical or box-shaped product by drawing it through a die with a tool-steel punch.

Process characteristics : Secondary shaping processes, Discrete

Design principles

Parts can only be cylindrical or box-shaped. Parts are typically deep (depth: diameter ratio greater than 1).

Technical information

Drawing is possible with any ductile metal that is available in sheet form. The constraining draw ratio limits the extent of drawing. (LDR.)

Typical applications

Beverage cans, pots and pans, other containers of various shapes and sizes, sinks, and so on.

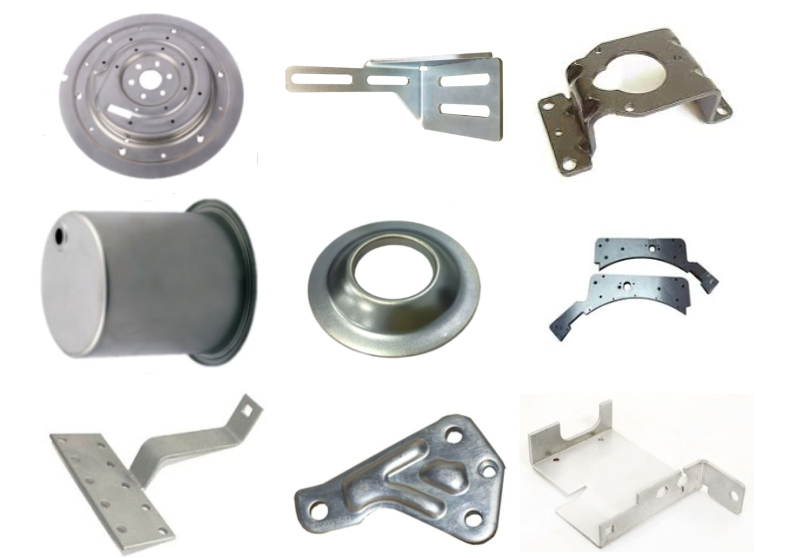

STAMPING

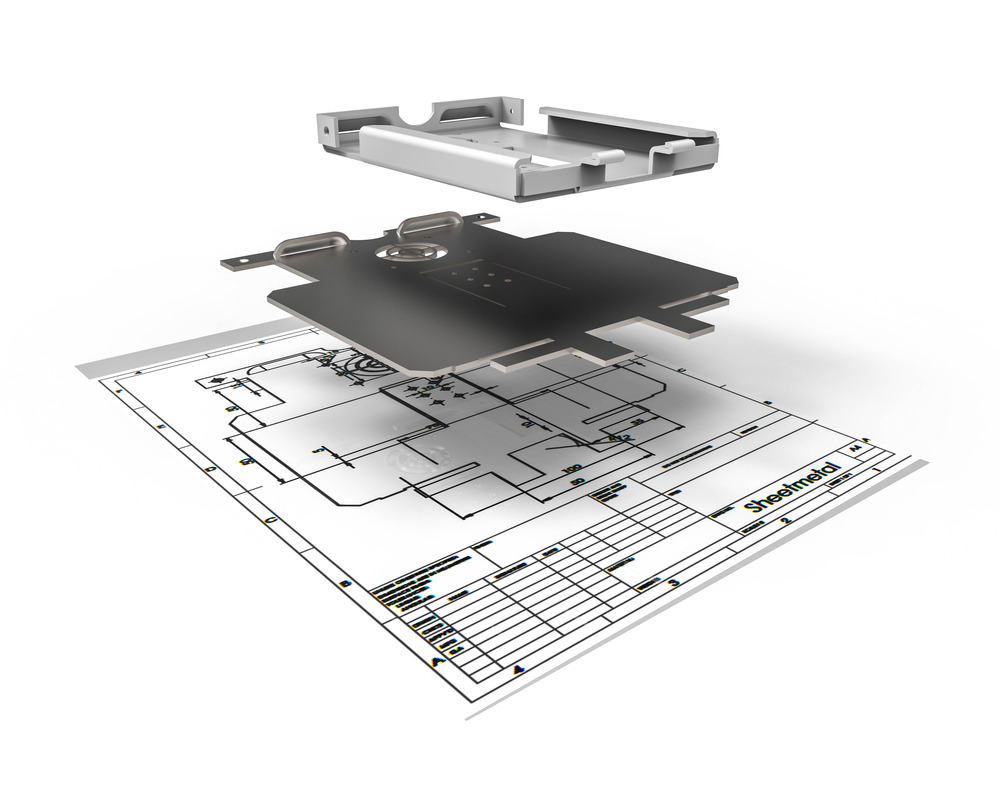

The process STAMPING covers a set of sheet forming operations carried out with the use of a die and press. Blanking, shearing, drawing, bending, shaping, coining, and swaging are some of the processes utilized.

Process characteristics : Secondary shaping processes, Discrete

Design principles

Shapes are formed from sheet stock, so their cross-sectional thickness is constant. Drawing/bending/forming operations allow for the creation of intricate shapes. Common shapes include holes, tabs, recesses, cavities, and raised portions.

Technical information

Metals, particularly steels, are the most widely utilized. Alloys of Al, Cu, Ni, Zn, Mg, and Ti are also utilized. Some polymers and composites can also be made by blanking/shearing, although the majority cannot.

The thickness of the walls is essentially uniform.

Typical applications

Brackets, mechanical components, pans, cups, key blanks, hinges, washers, tiny watch components, and so forth.

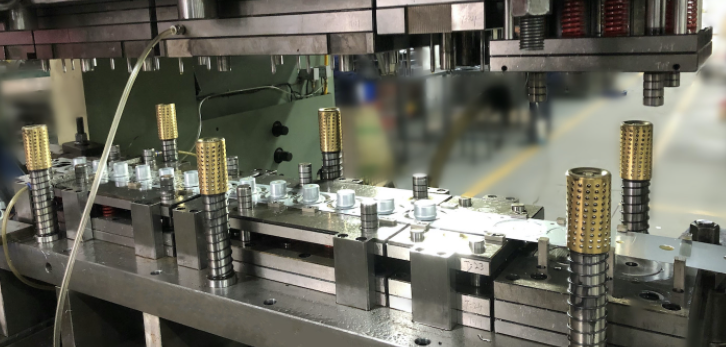

PRESS FORMING

The Method

The method PRESS FORMING includes a variety of sheet forming operations carried out with the use of a die and press. Blanking, shearing, drawing, bending, forming, coining, and swaging are some of the processes utilized. These operations can be carried out in a series to produce complicated forms. All forms created by this method, however, have a constant cross-sectional thickness.

Process characteristics : Secondary shaping processes, Discrete

Design principles

Shapes are produced from sheet material, thus their cross-sectional thickness is constant. Drawing/bending/forming processes allow for the creation of intricate forms. Common shapes include holes, tabs, recesses, cavities, and elevated portions.

Technical information

Metals, particularly steels, are the most widely utilized. Alloys of Al, Cu, Ni, Zn, Mg, and Ti are also utilized. Some polymers and composites can also be made by blanking/shearing, although the majority cannot.

The thickness of the walls is essentially uniform.

Typical applications

Body components for automobiles and truck panels

Other Types of Sheet Metal Processing methods Modulus Metal serves:

- Roll Forming

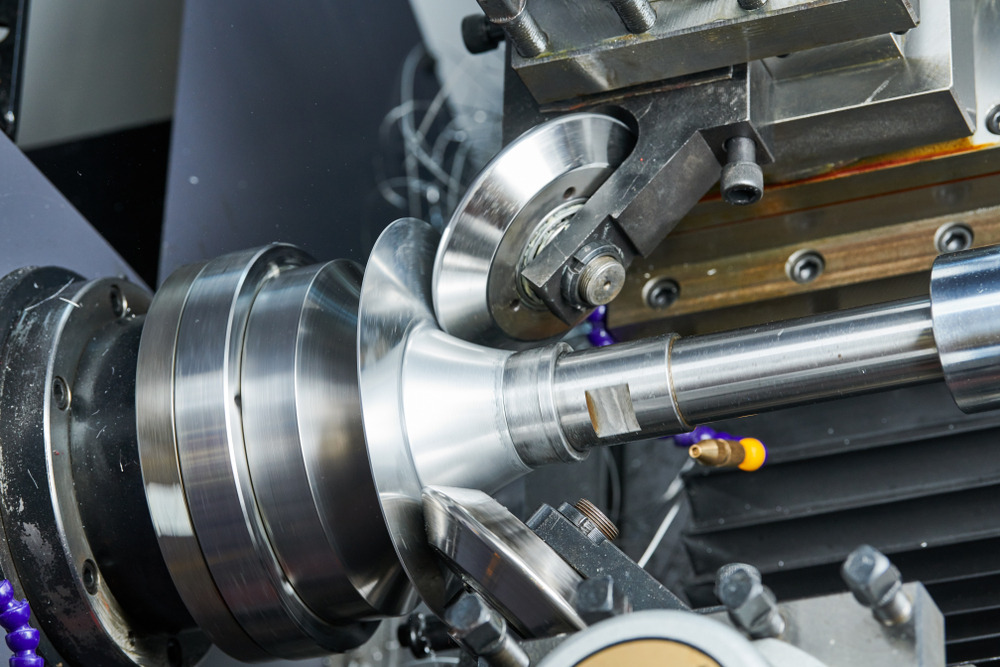

- Spinning