Modulus Metal | Manufacturer Company in TURKEY: Sand Casting | Investment Casting | Foundry | CNC Machining | Press Bending | Laser Cutting | Welding | Plastics Injection Molding |Turkiye

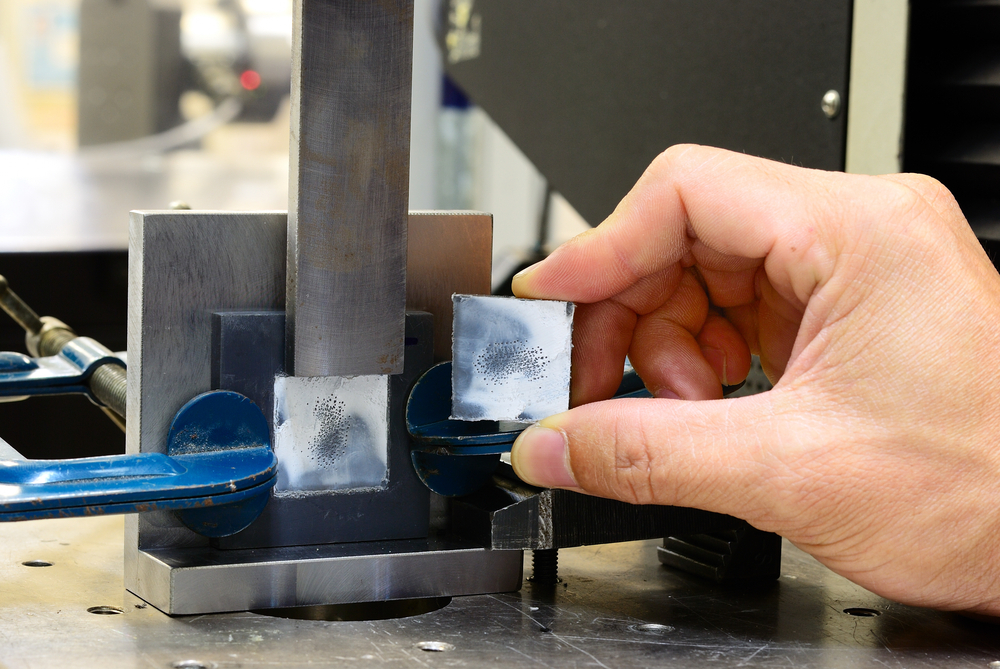

| Fracture Toughness & Toughness | Values |

|---|---|

| Fracture toughness | *133 – 147 MPa.m^0.5 |

| Toughness (G) | *89.9 – 110 kJ/m^2 |

| *Values indicated with asterisks (*) are approximate. No guarantee is provided for the precision of this information. |