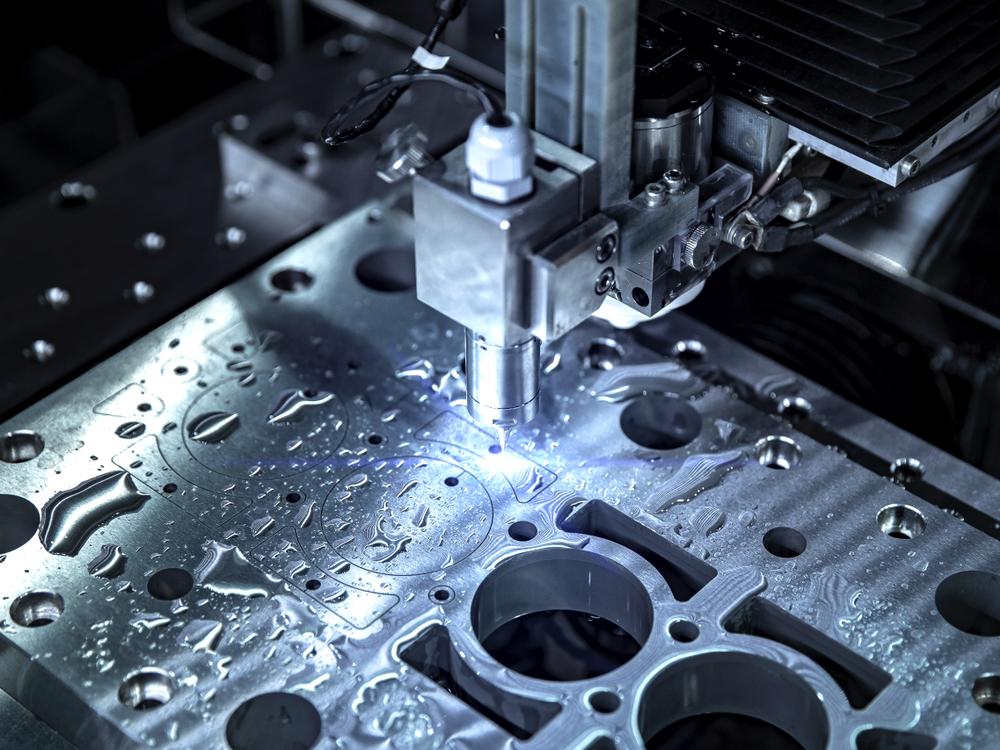

Abrasive Water Jet Cutting

Modulus Metal Company offers abrasive water jet cutting as a precision cutting solution for a wide range of materials, including metal. Using high-pressure water mixed with abrasive particles, our state-of-the-art equipment can make precise cuts with minimal distortion, even in complex shapes or difficult-to-machine materials. Abrasive water jet cutting is a cost-effective and versatile process that can be used in a variety of applications, including the production of automotive parts, aircraft components, and construction materials. Our team of experienced professionals is dedicated to providing high-quality services and delivering excellent results for our customers.

Water Jet Cutting

Modulus Metal Company offers water jet cutting as a precision cutting solution for a wide range of materials, including metal, plastic, wood, and glass. Using high-pressure water and the option to add abrasive particles, our state-of-the-art equipment can make precise cuts with minimal distortion, even in complex shapes or difficult-to-machine materials. Water jet cutting is a cost-effective and versatile process that can be used in a variety of applications, including the production of automotive parts, aircraft components, and construction materials. Our team of experienced professionals is dedicated to providing high-quality services and delivering excellent results for our customers.

Grinding

Modulus Metal Company offers grinding as a machining process for creating precise shapes and fine finishes on a variety of materials, including metal, plastic, and wood. Our skilled team is proficient in various grinding methods, including surface grinding, cylindrical grinding, and centerless grinding. We use state-of-the-art equipment to ensure accurate and consistent results for our customers. Grinding is often used in the production of automotive parts, electronic components, and medical devices, and we are dedicated to delivering high-quality services and excellent results for all of our clients.

Centerless Grinding

At Modulus Metal Company, we offer centerless grinding as a precise and efficient machining process for producing parts with high dimensional accuracy and smooth finishes. In this process, the workpiece is held between a regulating wheel, which rotates the workpiece, and a grinding wheel, which removes material from the surface. The regulating wheel is typically made of a softer material, such as rubber, while the grinding wheel is made of a harder material, such as aluminum oxide. Centerless grinding is often used in the production of automotive parts, electronic components, and medical devices, and our team of skilled professionals is dedicated to delivering high-quality services and excellent results for all of our clients.

USEFUL INFO

List of Important ISO Standards for Grinding