Modulus Metal is a company that provides surface coating services to improve the appearance, corrosion resistance, and wear resistance of various materials, including steel. Our team of experts is trained in various surface coating techniques, including laser/plasma clad and roll/explosive clad.

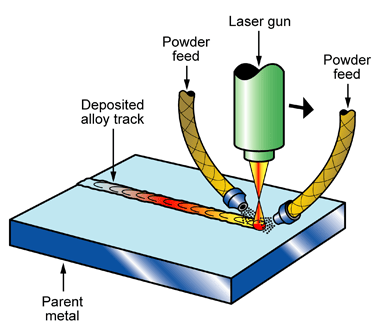

Laser / Plasma Clad

Laser/plasma clad is a process that involves using a laser or plasma torch to melt and fuse a layer of a metal or alloy onto the surface of a material. The laser or plasma torch is used to melt the metal or alloy, which is then deposited onto the surface of the material. This process provides a high-quality, precise coating that can be used to repair or improve the surface properties of a material.

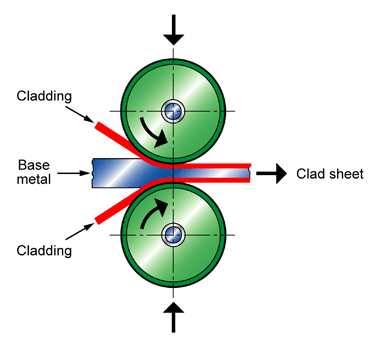

Roll / Explosive Clad

Roll/explosive clad is a process that involves using rolling or explosive force to bond a layer of a metal or alloy onto the surface of a material. In roll clad, the metal or alloy is placed between two rolls, which are used to apply pressure to the material and bond the coating onto the surface. In explosive clad, the metal or alloy is placed on top of the material and an explosive force is used to bond the coating onto the surface. This process provides a high-quality, precise coating that can be used to repair or improve the surface properties of a material.

Modulus Metal is committed to helping its clients improve the surface properties of their materials through the surface coating. Contact us today to learn more about our services and how we can help you achieve the desired properties for your materials.