Investment casting purchasing requires a high level of professionalism, thus buyers must be knowledgeable about investment casting’s related technical aspects and be able to effectively engage with foundry experts. Here, we outline some crucial considerations for customers purchasing precision investment castings.

A. Selection of Investment Casting Foundry

Both parties must work closely together and put up joint efforts in order to obtain investment castings of the utmost quality (supplier & purchaser). Before buying castings, buyers must invest some time in developing suppliers. Prior to the design of investment castings, communication between the purchaser and foundry is crucial, in addition to selecting a trustworthy investment casting supplier. As a result, developing long-term, mutually beneficial cooperation and positive interactive relationships should be the main goal of buyers and sellers. There are now two basic types of investment casting production techniques. One is the water glass casting process, which uses a type of pattern material made of paraffin and stearic acid and a water glass shell. The second method uses medium frequency induction melting, a rapid pouring procedure, high quality medium temperature pattern material, and the entire silicon sol shell. The water glass casting process is inexpensive, but it has poor size accuracy and surface smoothness. It is challenging to generate a high level of investment casting, which is usually utilized to produce carbon steel and low alloy steel castings. However, the silica sol casting technique can create components with excellent surface quality and high dimensional precision. It can compete with or even outperform investment castings on a global scale. Therefore, casting buyers must first comprehend the foundry’s production technology and detecting techniques in order to assess if the foundry can provide investment castings of the anticipated quality. Additionally, you must be aware of the foundry’s management structure and production capacity to guarantee timely delivery of large orders for high-quality castings.

B. Outline the Investment Casting Process

The adaptability of the structure design is one of the key benefits of investment casting. Therefore, the casting buyer should first become familiar with the investment casting process’ design principles. The parts’ structure should be in accordance with investment casting specifications, with an emphasis on achieving consistent wall thickness and ease of mold release, shell fabrication, filling, and cleaning. As a result, shrinkage cavities brought on by local overheating will be avoided, and a favorable temperature distribution and solidification order will be established. To make filling, cooling, and deoxidization easier, the part’s corner should have the proper casting round corners. Engineers who are competent in the casting process, particularly when designing new products, should be included in order to make casting design and material selection more reasonable, make it simple to ensure casting quality, and lower the cost of investment castings.

C. RFQ and Its Details

When submitting an RFQ to an investment casting foundry, buyers should make an effort to accurately and thoroughly describe the material and technical quality requirements, including the necessary machining sections, locating datum, heat treatment, surface treatment, packaging requirement, inspection and test items, and inspection report, among other things. It must be stated where the delivery will take place, how many castings are needed annually, and how much of each order there will be. To make the foundry quote easier, it is best to include the casting weight. Other crucial elements to take into account are the delivery schedule and the terms of payment, both of which must to be mentioned at the time of enquiry or quotation.

Unnecessary requirements will make manufacturing more difficult and may also have an impact on production costs and price, which is bad for both the buyer and the foundry. Requirements regarding the casting quality should be practical, appropriate, and fair in order to meet the use function. The tolerance grade sequence for casting sizes has been established by ISO8062, but there are no regulations that should be applied to the precision grades for investment casting. CT5 is for smaller sizes less than 50mm, although CT5 is typically used for steel castings between CT5 and CT7. If the size is greater than 100mm, it will be challenging to achieve such accuracy. In order to use the ISO8062 standard, customers must take the casting’s size into account.

The tolerance standard for investment casting, which can be used as the reference for size tolerance for exported investment castings, was created by the American association of investment casting (ICI) and the German association of investment casting (VDG), respectively. As a general tolerance for investment casting machining, ISO2768 is the tolerance standard for the metal machining process. It is not appropriate in some drawings to use ISO2768-mk as the general casting tolerance directly, however it is acceptable for some precision castings with sizes smaller than 60mm.

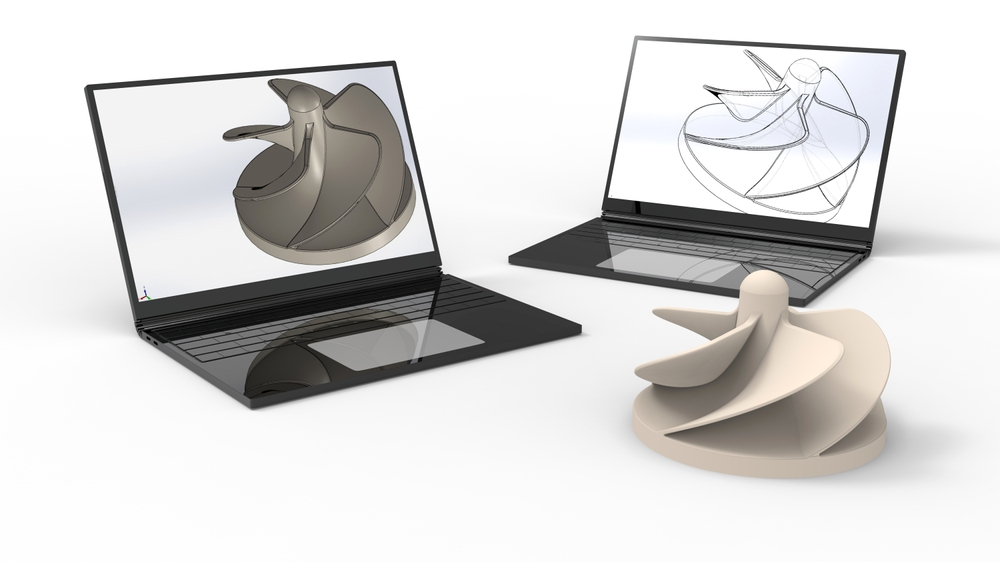

D. 2D Drawing and 3D Solid Model Data of the Casting Parts

The basic base for quotation and production is the part drawing, and sufficient details might help to prevent misunderstandings. The name of the part, the material, the tolerance, the surface roughness, the critical dimensions, the permissible residual gate height, the processing base, the processing surface, the machined surface, the modify content, the inspection requirements, the heat treatment and surface treatment requirements, etc. should all be clearly displayed on detailed drawings. We advise casting buyers to map the finished machining drawing and the casting separately. When the customer has specifications for the placement of the internal gate, the separating surface, and the plunger, the location must be specified or the requirement cannot be included in the drawing. For complex castings with irregular shapes, 3D drawings should be provided; this will help the foundry interpret the designs accurately and create the casting mold.

E. Sample Parts and Mold Approval Stage

Investment casting production begins with the design and manufacture of the mold; the cost of producing the mold is typically included in the quotation alone, is a one-time expense, and should be paid in advance by the buyer. Naturally, mold ownership normally belongs to the buyer. The foundry may store and utilize the mold, but both parties should come to an agreement before beginning any mold-related business. Due to process requirements, when foundries must alter the initial drawing design, they must map casting or separately send revisions to the buyer for approval before creating a mold. When the mold is prepared, the foundry must first give the buyer samples so they may inspect the size, assembly, or conduct the necessary tests. The buyer can only begin mass manufacturing when the sample passes testing. For some out-of-tolerance dimensions that won’t impair usage function, customers can use them directly and don’t need to adjust the mold, despite the fact that it’s not always very simple to modify some sizes. In this situation, it is preferable to request that the customer change the drawing tolerance in accordance with actual samples, or to request a written note when confirming a sample, in order to avoid a conflict during future mass production.

If the design is changed after the drawing or sample has been examined, an appropriate mold-fixing cost will be assessed. Therefore, the purchasing party must carefully analyze the drawings and maintain open communication with the manufacturer prior to creating the mould. The foundry may utilize a different type of material with a comparable or identical shrinkage rate after reaching an agreement with the customer, but the sample will only be used to check the size and geometry shape. Once more, drawing materials will be used for mass production. Prior to mass production, the sample must be reconfirmed when the mold is moved between foundries due to the use of various wax ingredients, shell materials, and technological factors that could influence the shrinkage rate.

F. Placing an order | PO for Mass-Serial Production

Purchasers should verify that the following issues have been addressed before placing a production order for investment casting:

- After the mold is made, the foundry may focus just on a few key sizes while mass producing castings because the mold will ensure multiple casting dimensions. The key control size, surface requirement, and acceptance criteria must all be specified in detail by the buyer. This crucial information will facilitate quality control during production and boost productivity.

- Place order early. There are numerous auxiliary operations involved in the investment casting process, thus the manufacturing cycle is lengthy and takes about a week from injection to pouring. Castings with holes or blind holes will require more drying time before shell production. The quality of the casting surface will be impacted by insufficient drying time, and it may even result in casting scrap. Castings require sufficient cooling time after pouring before moving on to cleanup. In order to ensure prompt delivery, the customer should be aware of the required shell-manufacturing and cleaning time when making a purchase.

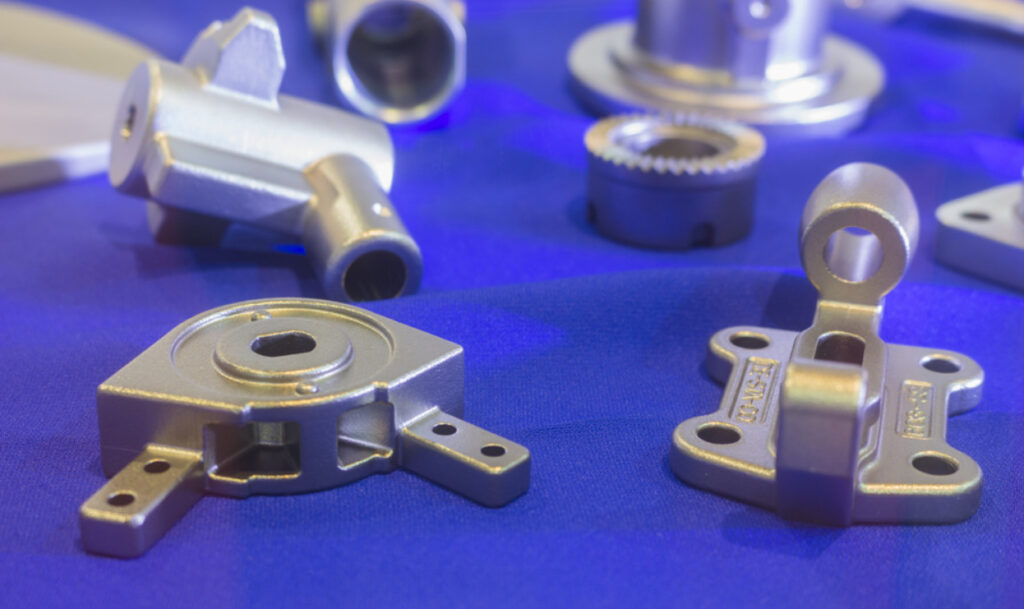

SAMPLES OF INVESTMENT CASTING PARTS MANUFACTURED BY MODULUS METAL