The capacity assessment services offered by Modulus Metal examine and assess a supplier’s capacity to meet both present and future production needs from customers. A risk evaluation approach drawn from best practices acknowledged in the industry is used to execute the assessment.

The qualified assessors at Modulus Metal, working with the supplier, summarize and report on competency and capacity, identify any relevant risks, and provide clearly defined risk mitigation strategies and action plans for everything from single assessments to completely managed survey programs.

The following key capabilities are used by Modulus Metal in accordance with customer requirements:

EMPLOYEES

Resources in the field with experience and a track record who are qualified to plan, carry out, report on, and follow up on all assessment-related duties

ASSESSMENT PROCESS

Standard work packages that have been proved in the industry, comprising checklists and forms

REPORTING

Supplier performance detailed reporting format provides a real status and performance analytics of suppliers.

Elements of Capacity Assessment

1. Facilities: Evaluate the space allocation, surroundings, maintenance schedules, and environmental concerns.

2. Review of Personnel :Evaluate resource management, identification of crucial skills, training, and personnel retention

3.Equipment and Tools: Evaluate usage rates, the identification of key tools, the maintenance plan, investment initiatives, and financials

4.Sub-Tier Suppliers: Evaluate purchasing, requirement flow-down, quality control, and inventory management systems and processes

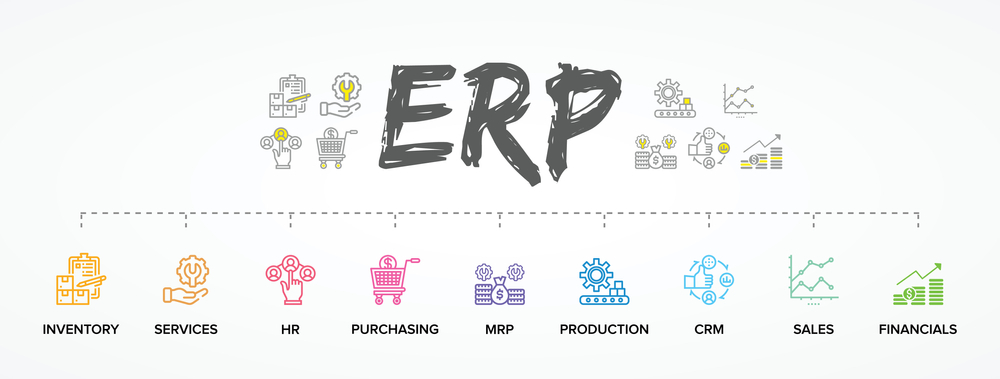

5.Production Planning: Evaluate the capacity estimation method, resource distribution, specific product line tactics, and MRP/ERP.

6.Performance of Delivery: Examine the success of lean manufacturing efforts, improvement programs, and schedule adherence.

MODULUS METAL PROVIDES

-Based on unique customer requirements, best practice capacity assessment services

-Single evaluations to completely organized survey programs

-Qualified assessors as per technology and product commodity

-Detailed and specific capacity indicators

BENEFITS OF CUSTOMERS

-Dependable supplier selection and qualification

-Identifying potential dangers that can disrupt business continuity

-Analyze the supplier’s readiness for changes in production demand

-Aid in the creation of exit planning and supplier strategies