Exporter Company | Modulus Metal | TURKEY

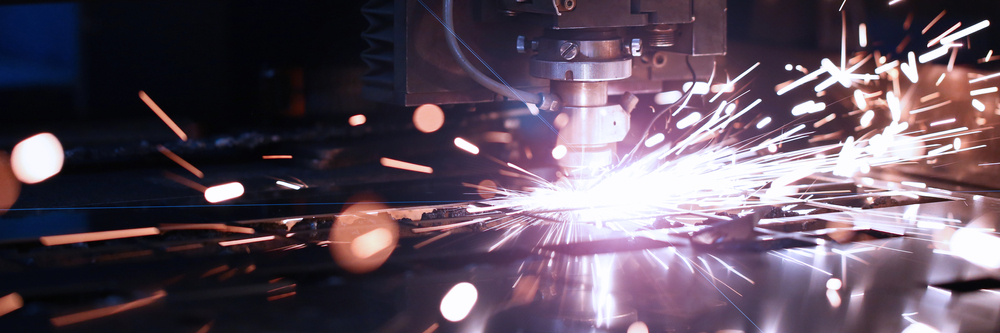

PLAMA CUTTING TYPES OFFERED BY MODULUS METAL

Precision Plasma Systems : To obtain the best cuts on a variety of conductive materials, use a variety of gases including oxygen, nitrogen, or a mixture of hydrogen, argon, and nitrogen. These CNC-controlled devices are made to generate the most accurate cuts possible with plasma.

Conventional plasma systems: Typical shop air is used as the plasma gas in conventional plasma systems, and the torch’s nozzle determines the form of the arc. Handheld systems fall under the category of traditional plasma systems, as do uses where the tolerance of the materials being cut is smaller. Even though two kinds of plasma cutting are prevalent, the other kind is more exact.

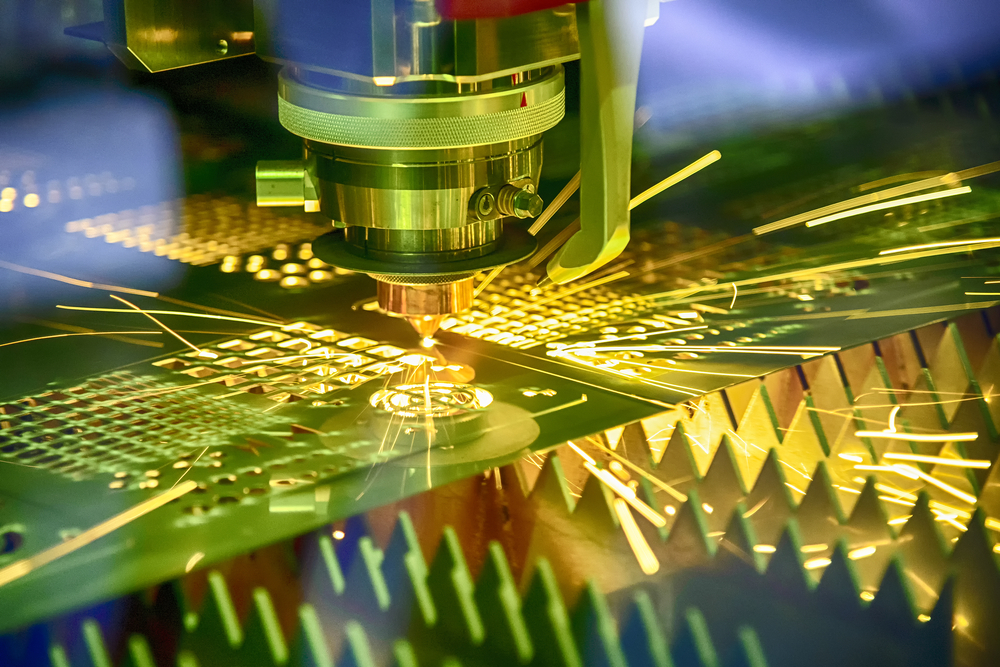

LASER CUTTING TYPES OFFERED BY MODULUS METAL

Fusion cutting, flame cutting, and remote cutting are the three main types of laser cutting.

Which Laser Cutting Techniques are Used for Sheet Metal?

Fiber Lasers, CO2 Lasers, Direct-Diode lasers

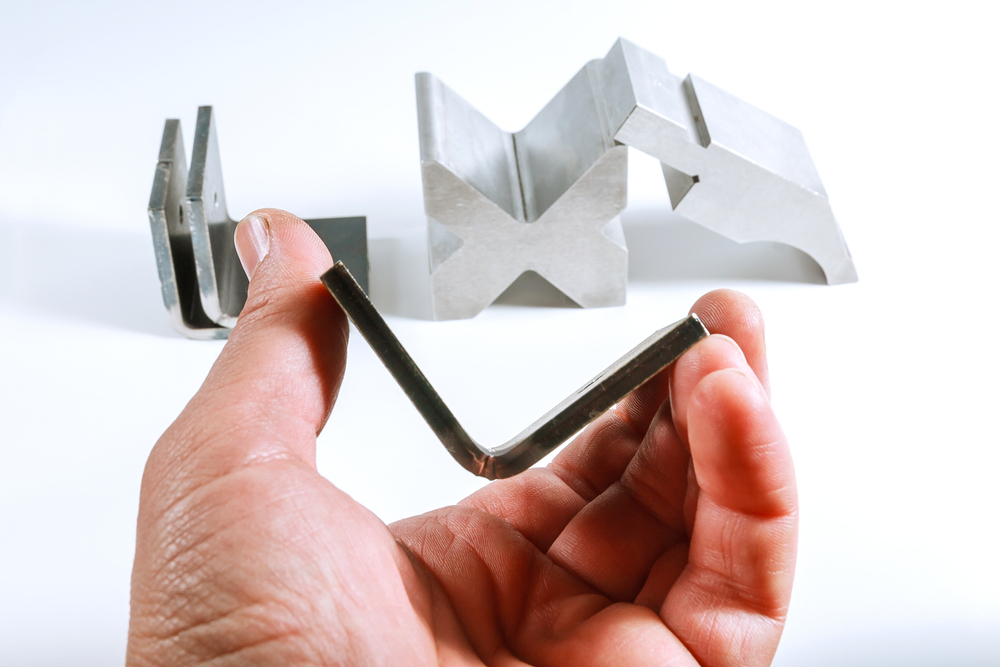

BENDING METHODS TYPES OFFERED BY MODULUS METAL

Air Bending: Air bending is a method of bending a workpiece by bringing it into contact with the edge of a die and the tip of a punch. The punch is pushed past the top of the die into a V-shaped opening, without coming into contact with the bottom of the V. The size of the V-shaped opening at the bottom of the die determines the inside radius of the bend. The operator can switch out the bottom dies to make adjustments or change the design. Air bending is not typically done on older mechanical machines.

Bottom bending: Bottom bending involves using die angles that match the intended angle of the workpiece. The workpiece is pressed against the die, and the radius of the punch is forced into the material to create the angle. When the pressure is released, the material will spring back slightly, so it’s important to over-bend the material by a few degrees to account for this springback.

Coining: Coining is a bending method that involves stamping the workpiece between a punch and a die. The right amount of pressure allows the punch tip to penetrate and flow into the material, resulting in an accurate and highly repeatable bend. This method can be used with older machines as well.

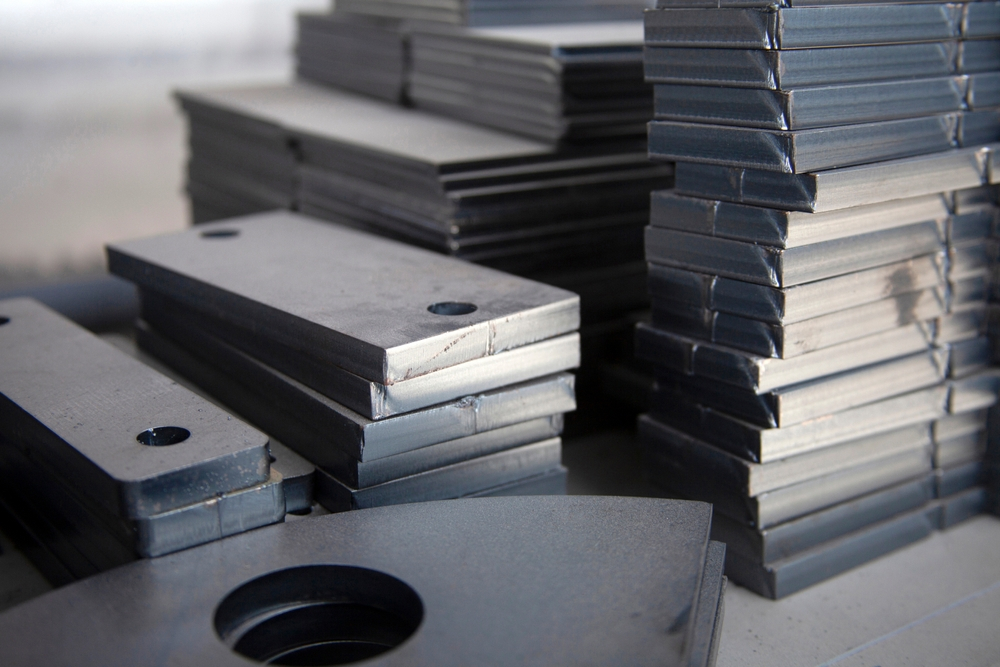

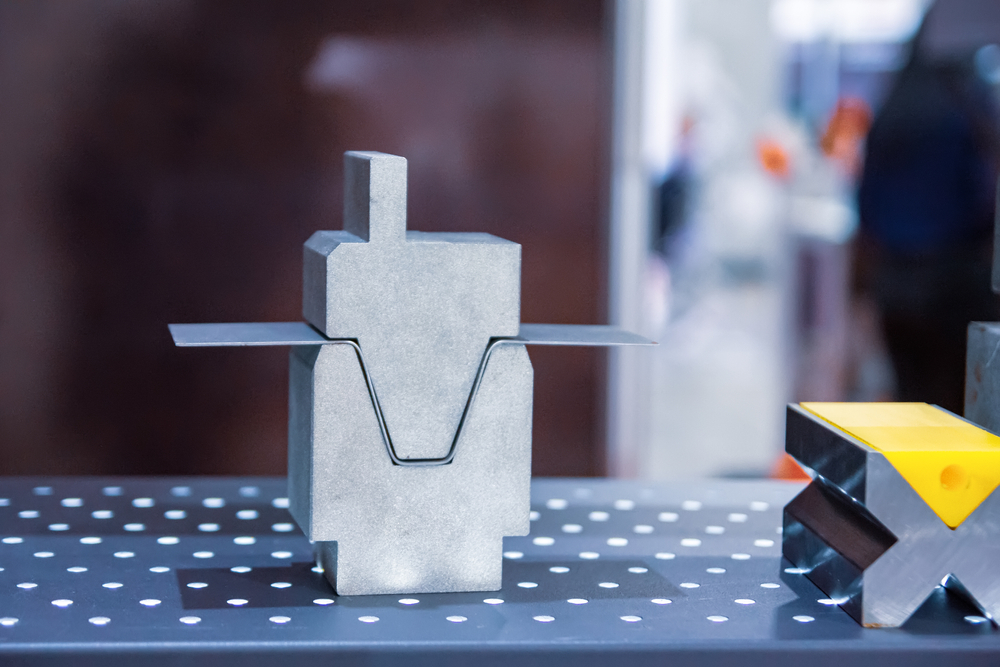

PRESS BRAKE TOOLING TYPES OFFERED BY MODULUS METAL

It is important to verify that the punch and die tooling meets the manufacturer’s specifications and tolerances every time they are used. The operator is responsible for ensuring that the tooling fits properly and making any necessary adjustments.

There are several types of dies that can be used in press brake operations, including:

- Rocker-type dies, which bend metal by moving up and down and side to side

- V-dies, which are used to create V-shaped bends

- Multiple bend dies, which are designed to form specific shapes and can make several bends in one motion

- Acute-angle dies, which are used to create acute, obtuse, and right angles

- Seaming dies, which create seams in sheets and tubes

- Offset dies, which are punch and die sets that create two angles with a “Z” shape

- Curling dies, which are used to curl and coil the edges of sheets

- Gooseneck dies, which are used to clear flanges or protrusions on workpieces

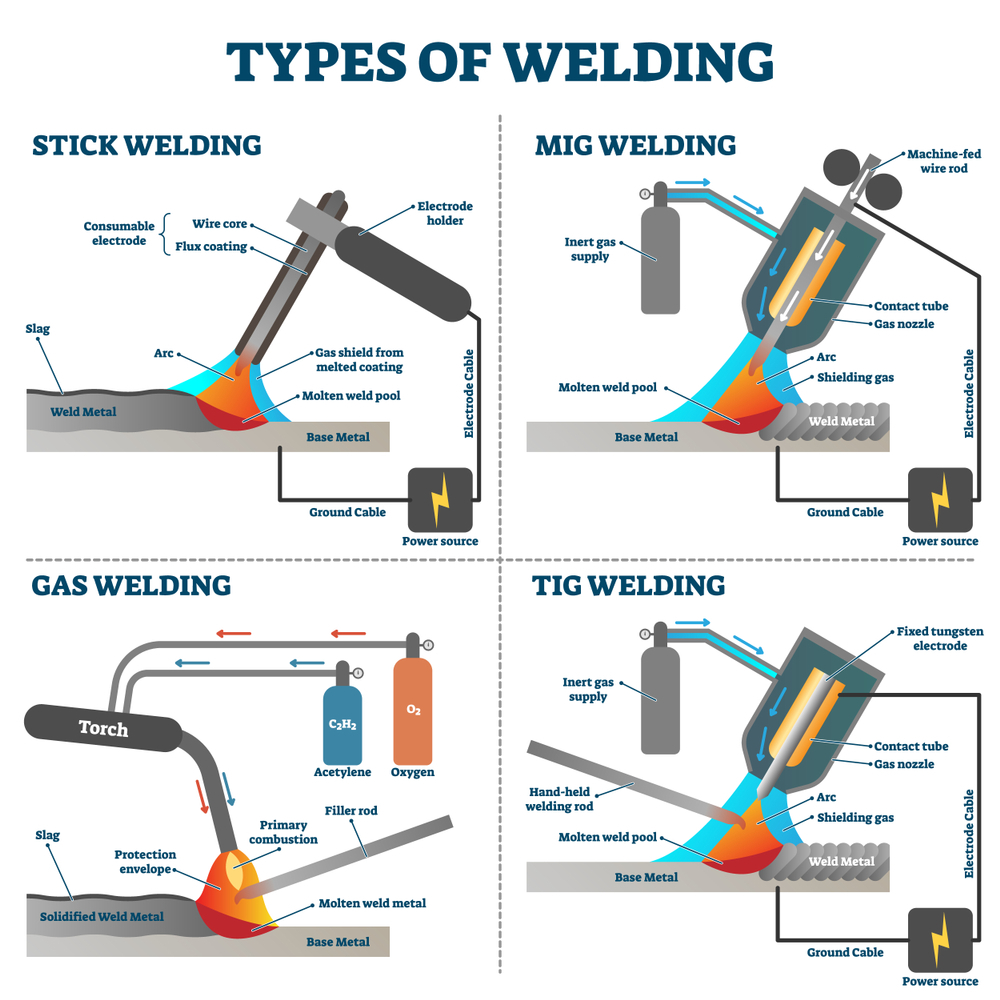

WELDING TYPES OFFERED BY MODULUS METAL

SMAW, or shielded metal arc welding

A flux-coated electrode is used in shielded metal arc welding (SMAW) to produce a weld. Heavy-duty applications frequently use this kind of welding. The earliest type of welding is shielded metal arc welding, which is still employed in many applications today.

GMAW, or gas metal arc welding

A wire electrode is fed through a cannon in gas metal arc welding (GMAW). Because it is effective and creates welds of good quality, this sort of welding is frequently utilized in industries. The GMAW process type is MIG & MAG welding.

TIG, or tungsten inert gas welding (GTAW)

To generate a weld, TIG, also known as tungsten inert gas welding (GTAW), uses an electrode made of non-consumable tungsten. Due of the smooth, accurate welds it creates, TIG welding is frequently employed for smaller jobs.

Flux Cored Arc Welding (FCAW)

Flux-filled tubular wire is used in the Flux Cored Arc Welding (FCAW) method of arc welding. The flux core wire aids in producing high-quality welds by shielding them from contaminants.

Submerged Arc Welding (SAW)

With the help of an electrical arc that is submerged beneath the weld puddle’s surface, Submerged Arc Welding (SAW) joins metals together. SAW is an extremely flexible welding technique that can be used to join a wide variety of metal kinds. In heavy-duty applications where great strength and toughness are necessary, the technique is frequently used.