Stainless steel products are highly machinable, workable, uniform, and corrosion- and oxidation-resistant.

From the smallest medical instrument to the tallest tower, stainless steel is essential to modern life. This material is ideal for a wide range of applications thanks to its exceptional mix of strength, corrosion resistance, and attractive look.

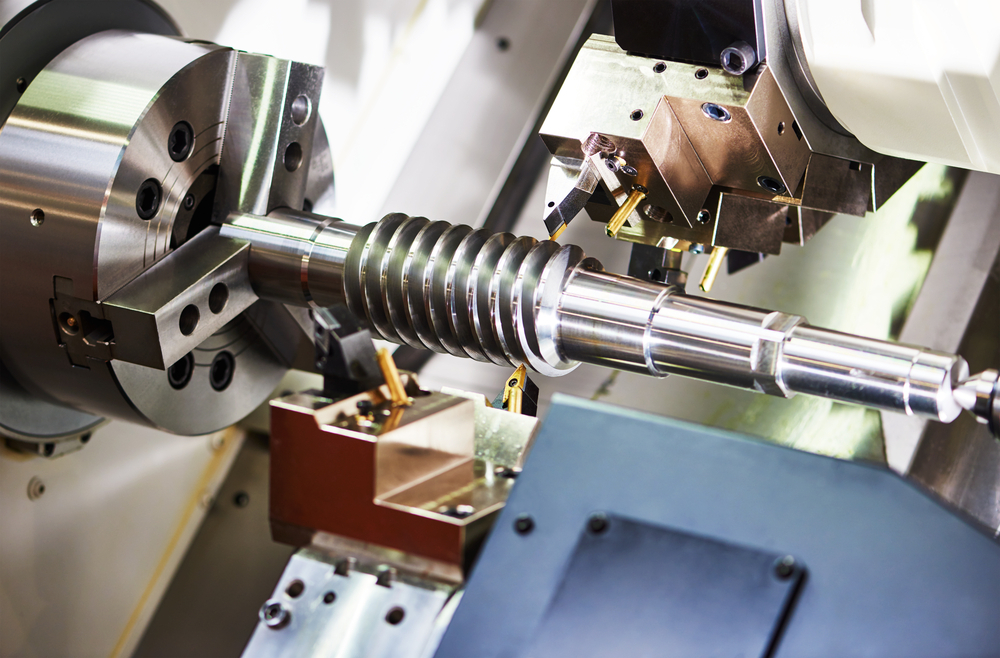

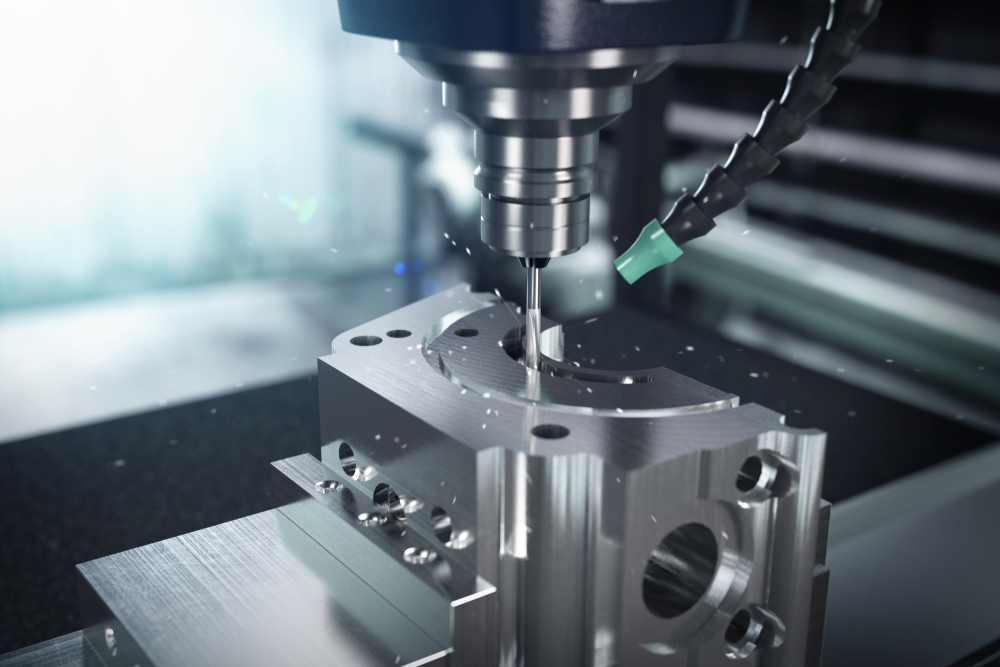

Use Modulus Metal to convert your stainless steel part or assembly from the print to the production stage. We have many machine shops with ISO 9001:2015 certification that specializes in producing high-value components and building complex assemblies for demanding settings. We can offer a variety of client-tailored services that expedite supply chains thanks to our cutting-edge machinery, highly skilled staff, and commitment to quality.

ADVANTAGES OF MACHINING STAINLESS STEEL PARTS

A class of iron-based alloys known as stainless steel has at least 11 percent chromium, a metal that resists corrosion and can endure high temperatures. This material is also completely recyclable and has a long cycle life, making it eco-friendly.

Only a few of the more than 150 stainless steel grades are utilized in common applications. The specific performance attributes will differ per grade, but the following features are typical.

Corrosion protection,

Strength

Beauty appeal

An enhanced weldability

Low weight

Excellent formability

in some circumstances, resistance to magnetism

Simple to clean

Endurance to high temperatures

Easily sterilizable

Endurance at low temperatures

STAINLESS STEEL PARTS INDUSTRIES

Stainless steel is the best material for a variety of applications because of its highly regarded performance qualities and ease of fabrication. In addition to being used to create surgical instruments and implantable medical equipment, it is also fashioned into auto exhaust systems, grills, and trim. The ability of stainless steel to withstand extremely hot and low temperatures, corrosive environments, and acidic conditions is valued by operators of crude oil and natural gas drilling platforms. The material’s rust resistance, cleanliness, and lack of flavor alteration make it ideal for kitchen applications. These are a few sectors that use stainless steel.

Gas and oil

Petrochemicals

Heavy machinery

Furniture

Catering Food Preparation

Agriculture

Automotive

Architectural

Construction

Electronics

Mining

Renewable energy

ALLOYS OF STAINLESS STEELS

Although Modulus Metal can machine, weld, and assemble any material, we most frequently use stainless steels from the 300, 400, and 17-4 series. When selecting stainless steel for a project, it is important to carefully consider each series’ distinctive performance characteristics.

STAINLESS STEEL 303

A chromium-nickel alloy with machinability and anti-seizing characteristics improved by selenium, sulfur, and phosphorus additions. It resists corrosion well and may be treated simply. Components like shafts, gears, valves, bolts, and screws that need to be machined, ground, or polished are typical examples of such components.

STAINLESS STEEL 304

A chromium-nickel alloy with an extremely low carbon content that resists magnetism. It possesses excellent resilience to intergranular corrosion following welding or stress relief, great malleability, and good corrosion resistance. Common applications include automobile heads, food processing equipment, screws, and machinery parts.

STAINLESS STEEL 316

A superior corrosion-resistant, a chrome-nickel alloy that resists magnetism. It can endure being among strong chemicals and saltwater. This material is frequently used in equipment for food preparation, lab apparatus, coastal paneling, marine components, chemical containers, heat exchangers, fasteners, and springs.

STAINLESS STEEL 410

Offers outstanding wear and corrosion resistance and contains 11.5% chromium. Pipelines, valves, nozzles, dentistry and surgical tools, and automotive components are just a few examples of common applications.

STAINLESS STEEL 420

A substance that gives enhanced strength, wear resistance, and increased hardness. It has strong corrosion-resistant qualities since it includes at least 12% chromium. Cutlery, medical devices, needle valves, and shear blades are all manufactured of this material.

STAINLESS STEEL, 17-4PH

Possesses exceptional levels of toughness, corrosion resistance, and strength. It is magnetic because it is martensitic. Pump shafts, oilfield parts, mechanical seals, and aircraft components are frequently made with them.

STAINLESS STEEL 17-4H900

A substance that successfully balances strength and corrosion resistance. It is magnetic and may be heated to precipitation-harden it. Aircraft components, nuclear machinery, food processing equipment, and paper mills are a few examples of applications.

STAINLESS STEEL 17-4H1150

A chromium-copper alloy that has been precipitation hardened and has high strength and a modest level of corrosion resistance. It is heat-treated to increase strength and magnetism. Valve parts, pump shafts, aerospace components, turbine blades, nuclear waste casks, offshore applications, food-processing tools, and machinery for the pulp and paper industries are a few examples of typical uses.

The following grades of steel can also be machined, welded, and assembled by Modulus Metal in addition to the ones on the previous list:

1018 \1045 \12L14 \4130 \4140 \A36