Within the supply chain, the function of supplier quality engineers, or SQEs, is to guarantee that standards of quality are respected when dealing with suppliers. Their job is to carefully coordinate suppliers and verify and examine each one’s operations to make sure they adhere to the high standards of quality set by the larger business. In addition to this, SQEs are in charge of carrying out supplier audits and developing quality control plans to make sure that efficient supply chains are possible.

Our Supplier Quality Engineering Service:

The scope of supplier quality engineering in the supply chain is extremely broad. We shall divide the supply chain path into three main segments:

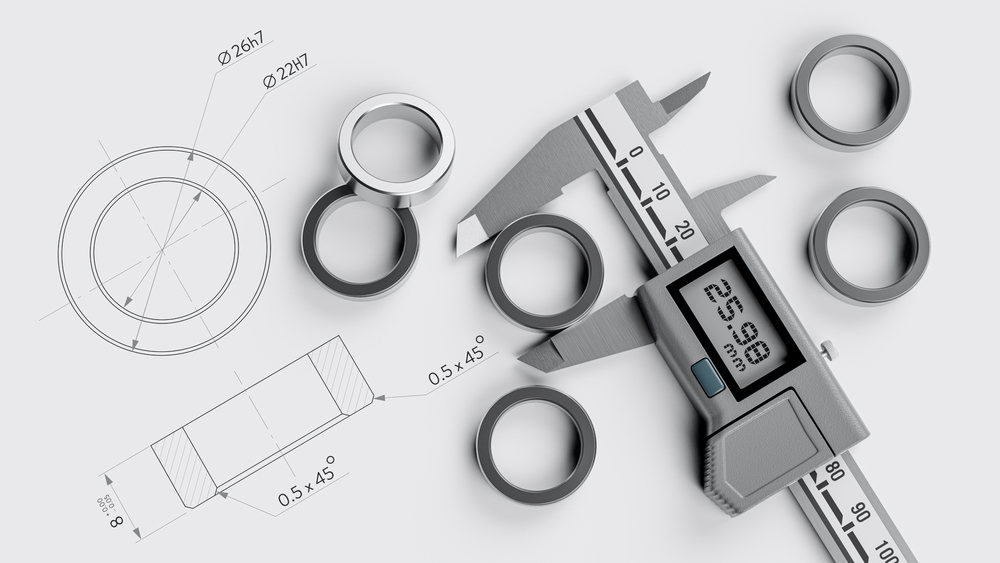

A. Audits, Assessments and Evaluations of Suppliers

The assessment of supplier and factory audits to make sure they are operating in accordance with the organization’s criteria often constitutes the first stage, which is carried out by SQEs. In order to ensure a seamless supply chain process, this enables decision-makers within the company to identify which suppliers match the quality required from the organization. Additionally, SQEs continuously analyze these services and offer suggestions for enhancements, which are then periodically implemented.

B. Introduction of new products

SQE supports the supervision of new products in addition to inspecting and auditing suppliers. This may entail monitoring and controlling processes as well as reviewing the effectiveness of product lines as they approach completion and wider distribution.

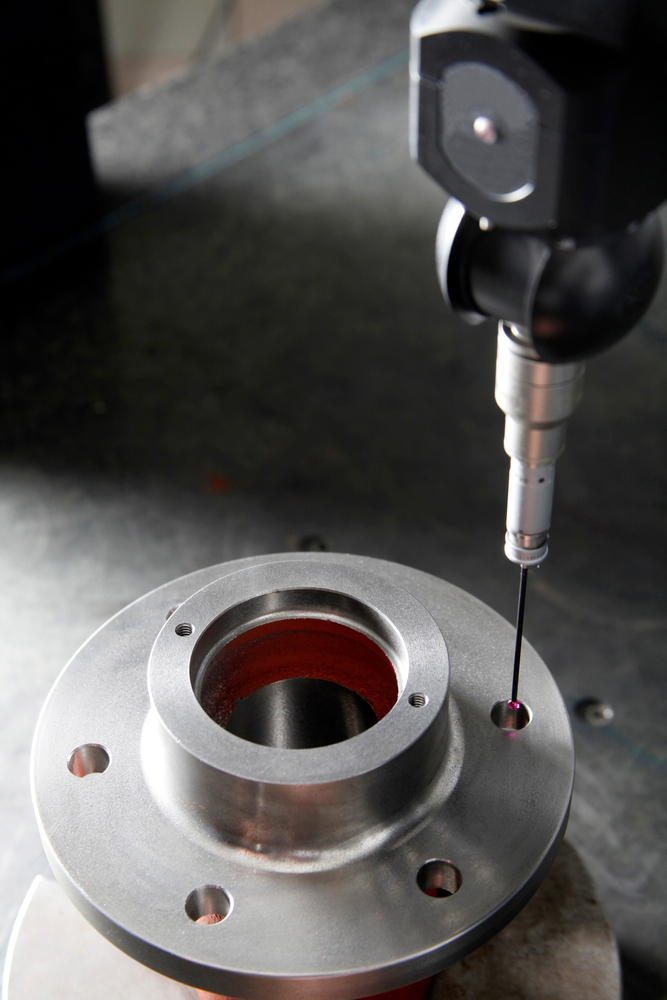

C. Serial Production

Once a product enters mass production, the SQE’s job is not done. When a product reaches this point, quality control is essential to ensuring that any flaws are discovered and fixed before they reach consumers and potentially harm the brand’s reputation. This is accomplished by thorough documentation of the inspections and operations on the production line. while addressing possible kinks and inefficiencies in the production line to continually improve it.

D. Further Services provided by Modulus Metal

-PPAP Approvals on site

-Lean Management

-Supplier Improvement

-Technical Supports

-Quality Controls

-Inspections

E. The Benefits of Using MODULUS METAL SQE Services Include:

• Effectively manage the entire process of new product introduction and mass production, boost production effectiveness, and guarantee seamless new product delivery following mass production.

• Assist in the multi-dimensional screening of superior products, speed up the launch of new initiatives, and reduce development costs for businesses;

• Boost initiatives to introduce new products, increase the effectiveness of new product development, and monitor and address product quality issues at various stages;

• Sporadic or recurring factory audits and improvement services to assist businesses in raising the caliber of their suppliers