Modulus Metal offers quality engineering, supplier-quality engineering, quality engineering consulting, quality engineering training and quality engineering support services for their customers supplying their goods from Turkey.

Through consulting, training, and project support, Modulus Metal provides Quality and Reliability Activities for Product and Process Development. According to your specific needs, goals, and preferences, Modulus Metal offers Knowledge, Guidance, and Direction in Quality and Reliability activities. Please allow us to assist you in understanding the value of quality engineering project support, quality engineering training, or quality engineering consulting.

QUALITY ENGINEERING SERVICE IN TURKEY

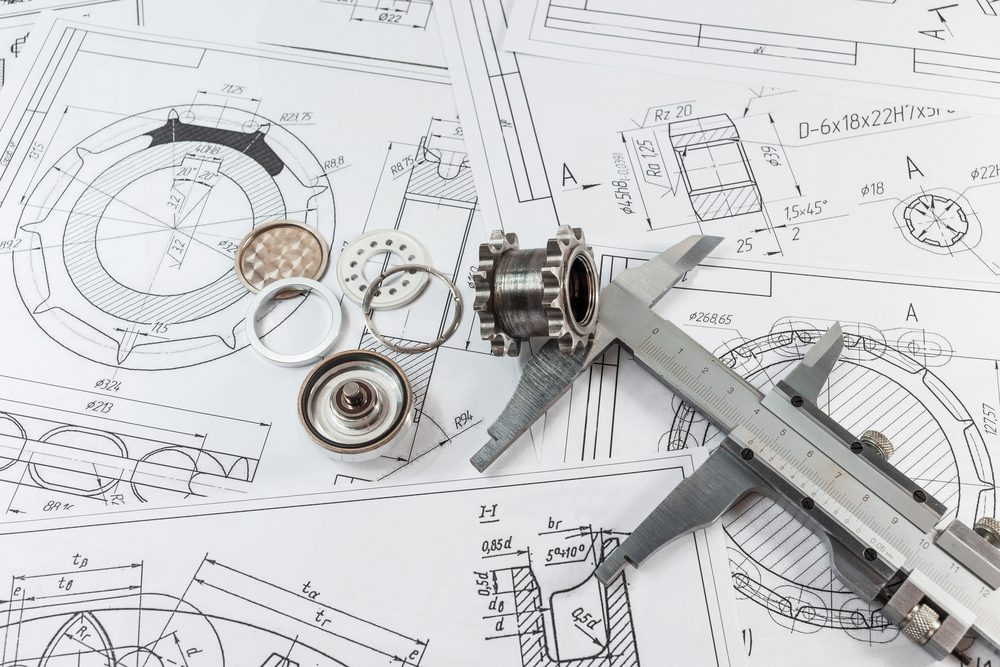

To ensure that products or services are conceived, developed, and manufactured to meet or exceed the customer’s requirements and expectations, quality engineering entails analysis techniques and the establishment of systems. Quality engineering is the study of a product’s design, development, and manufacturing processes with the goal of enhancing the product’s quality and the production process while identifying and minimizing waste in all of its various forms. Numerous business and engineering disciplines are frequently incorporated into the development and application of Quality Engineering methodologies and technologies. A wide variety of approaches and instruments fall under the umbrella of quality engineering, including but not limited to the following list:

The development, implementation, and administration of the QMS

From the initial design concept to the manufacture and monitoring of the finished product, Advanced Product Quality Planning (APQP) methods like Quality Function Deployment (QFD) and Failure Mode and Effects Analysis (FMEA) are used.

Incorporating VOCs into new product designs and manufacturing methods

*To guarantee that the materials, components, and assemblies fulfill the design and quality standards, working with internal and external suppliers

*Identifying and getting rid of waste in business and manufacturing operations

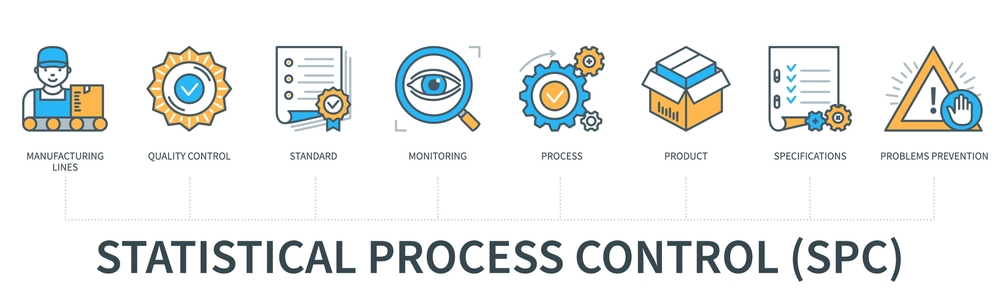

*Putting in place and maintaining process controls like statistical process control (SPC)

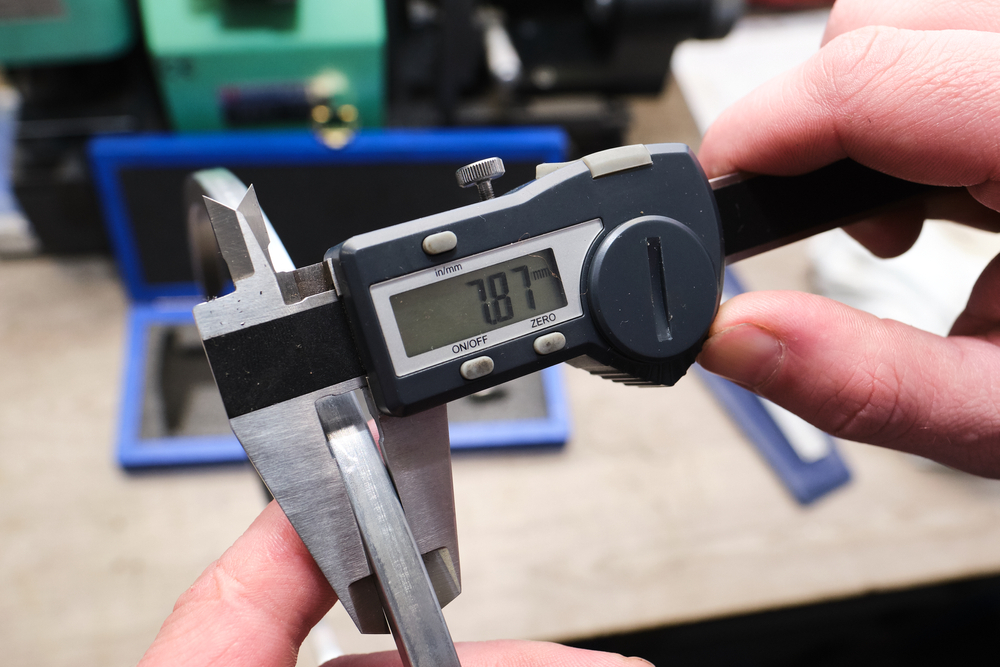

*Creation of suitable tests and inspections to verify the effectiveness of process controls

*Working with customers to address any quality concerns by using Root Cause Analysis (RCA) and problem-solving techniques like the 5 Why method, the 8D technique, cause-and-effect diagrams, etc., and putting in place efficient steps to stop the problem from happening again.

Within the field of quality engineering, quality engineers are the key players in creating, implementing, and maintaining the many quality disciplines. They are experts who have developed a deep awareness of quality principles, as well as of the evaluation and control of products and processes. Developing, putting into practice, and maintaining the systems that are used to gauge, watch, and regulate the quality of the production process’s products and processes are often the responsibilities of quality engineers. They collaborate with design and production teams to set quality standards for products and the production procedures that go with them. Process capability and the application of SPC in manufacturing process monitoring are concepts that quality engineers need to be aware of. They frequently also construct proper end-of-line tests, specify the parameters, and establish acceptable limits for the outcomes.

The Quality Engineer must also have extensive knowledge of the use and application of process improvement, troubleshooting, and problem-solving tools. To guarantee that quality standards are followed and the needs and expectations of the customer are fulfilled or surpassed, a quality engineer must be able to identify and comprehend process concerns and devise effective countermeasures, including process or product adjustments, as needed.

The advantages of quality engineering are numerous and can significantly impact product quality, process effectiveness, and general customer happiness. Please get in touch with a member of our knowledgeable staff at Modulus Metal if you’d like more information about how Quality Engineering techniques and equipment might benefit your company.

SUPPLIER QUALITY ENGINEERING SERVICE IN TURKEY

Supplier quality refers to a supplier’s capacity to provide consumers with products or services that meet their needs. A proactive and collaborative strategy is used to manage supplier quality in a system known as supplier quality management.

It is in the best interest of a business to make sure that its service or material suppliers are offering the best goods and services while also adhering to pre-established standards. This is frequently achieved by using supplier quality management systems (QMS), which enable businesses to keep an eye on supply chains and check or audit products and services on a regular basis.

Early on in the process of product design and supplier selection, supplier quality control is implemented. It continues throughout the duration of the partnership with that specific supplier and throughout the life cycle of the product. Effective and efficient supplier quality management strategies involve taking inputs (such as employee labor, market demands, operating finances, raw materials, and supplies) and turning them into outputs that customers find useful.

Quality management and supplier performance go beyond negotiating the best bulk material prices or attaining a cheap purchase price. It also contains:

-The price of dealing with problems, communicating, transferring vendors, and conducting transactions

-The consistency of the supplier’s deliveries and the supplier’s internal procedures (e.g., inventory levels, all impact supply-chain performance)

A PROPER SUPPLIER QUALITY MANAGEMENT PROCESS HAS MANY BENEFITS.

Multiple suppliers for the same raw material were historically commonplace, typically because of worries about stock running out or a desire to compete with different suppliers for price breaks. This has been replaced by closer collaboration with fewer suppliers through long-term, partnership-focused agreements.

The advantages of supplier alliances include:

Critical process inputs are less likely to vary when using fewer vendors.

If the suppliers have shown to be successful at managing their output, there will be less need for regular monitoring of the suppliers and the products.

To establish a successful supplier management process, you must:

-Building relationships based on trust will help you reduce risk by sharing your knowledge and resources.

-An awareness of the distinct roles played by both firms in the process

-Support from CEOs or top management of both participating companies

STRATEGIES AND CRITERIA FOR SUPPLIER SELECTION

A cross-functional team of of representatives from several divisions of a company should establish the criteria for selecting suppliers for a specific product or service category. For instance, the team at a manufacturing company would normally include individuals from purchasing, quality, engineering, and production. Members of the team should have technical or application expertise of the good or service being purchased, as well as come from the department using the item.

Typical factors used to choose vendors and suppliers include:

*Ability to meet current and potential capacity requirements on the desired delivery schedule

* Prior experience and performance with the good or service to be purchased

* Relative level of sophistication of the quality system, including meeting regulatory requirements or mandated quality system registration (e.g., ISO 9001)

*Financial stability, availability of technical assistance, and assistance in formulating and improving processes.

*Total cost of doing business with the supplier, including material costs, communication strategies, inventory needs, and incoming verification requirements.

*Supplier history of enhancing business performance.

*Total cost assessment.

How to assess whether a prospective provider closely matches the chosen criteria:

*Formally requesting a quote, including specifications and additional demands, such as testing, from the supplier.

*Management and/or the selection team visits the supplier a written survey, an on-site evaluation, or a request for a certificate of quality system registration can all be used to confirm the status of a quality system.

*Discussions with other clients that the supplier serves examining databases or trade publications for the supplier’s product line

*Evaluation of samples obtained from the supplier, such as prototyping, lab testing, or validation testing.

QUALITY ENGINEERING CONSULTING IN TURKEY

For businesses who are either beginning to create a strategic quality strategy or who are aware that their current quality systems require improvement, Modulus Metal offers Quality Engineering Consulting.

Our group of knowledgeable topic matter specialists can offer:

*Advice on creating a strategic plan to adopt quality engineering in your company

*Insight into your quality systems’ efficiency and present state while establishing or enhancing your Quality Engineering processes, provide guidance and coaching to your management teams.

*Templates and documents needed to hasten the creation and implementation of your quality assurance and control systems

Your quality engineering processes can go forward with the help of quality engineering consulting offered by Modulus Metal. Your organization’s ability to effectively adopt Quality Engineering processes and tools will enhance collaboration between the engineering and production teams and guarantee that the VOC is incorporated into new or enhanced goods and services. Through more effective processes and decreased waste, quality engineering tools can raise product quality while lowering production costs. You may generate high-quality products that match or surpass your consumers’ demands and wants while cutting down on development time and costs, which will have a significant impact on your bottom line.

QUALITY ENGINEERING TRAINING SERVICE IN TURKEY

Proper training is one of the most effective strategies for assuring success in any new activity. Your Quality Engineering implementation process will be significantly impacted by appropriate training delivered by skilled people with extensive experience in their industry. We at Modulus Metal has the expertise, knowledge, and passion for quality necessary to provide highly efficient Quality Engineering Training. Additionally, we provide specialized training on a number of important quality techniques, such as FMEA, 8D, RCA, MSA, A3, 5 Why, and QFD, among others. Additionally, Modulus Metal offers a variety of training opportunities, including:

On-site Training: One or more of our expert engineers will conduct efficient, effective training for your teams at your location or that of your suppliers, utilizing real-world examples and experiences that are pertinent to your goods and procedures.

Regardless of the approach, investing in the quality engineering training offered by Module Metal is a smart move. Businesses make a variety of investments, including buying new machinery, supplies, and equipment as well as constructing new buildings. While each of these matters, nothing has a greater impact on an organization’s success than investing in its employees’ professional development. A success investment is one that is made in your workforce.

QUALITY ENGINEERING SUPPORT SERVICE IN TURKEY

Your Quality Engineering strategic plan will need the backing of upper management as well as a sizable quantity of committed resources. Many firms are being forced to work harder with less resources because of heightened competition or greater operational and material costs. In some circumstances, immediate long- or short-term help is required to achieve predetermined objectives. It can take time and money to find qualified permanent employees. At Modulus Metal, we have skilled personnel on hand and prepared to jump in and deliver results. We’ll have quality engineers who:

*To identify and handle risk and make sure quality is incorporated into your product designs, work closely with your design engineering teams.

*To cut waste and boost efficiency, audit your operations, evaluate performance, and suggest a course of action.

*Make suggestions for improvement while monitoring your processes and gathering data using statistical analysis techniques.

*To assure the quality of your processes, help your production employees with the creation and execution of procedures, work instructions, training, and process controls.

*Encourage and aid To find and eliminate waste in your processes, engage in continuous improvement activities with your teams.

*Take the initiative to engage your teams in cross-functional problem-solving activities, such as root cause analysis and the creation of both interim and long-term solutions.

Our highly qualified subject matter experts are accessible to help your objectives no matter what they may be. We have decades of expertise working in a variety of industries, including mining equipment, heavy construction, agricultural machinery, automotive, and aerospace. You may increase quality, decrease or eliminate waste, and meet or exceed customer expectations by properly implementing Quality Engineering methodologies and technologies in your business.