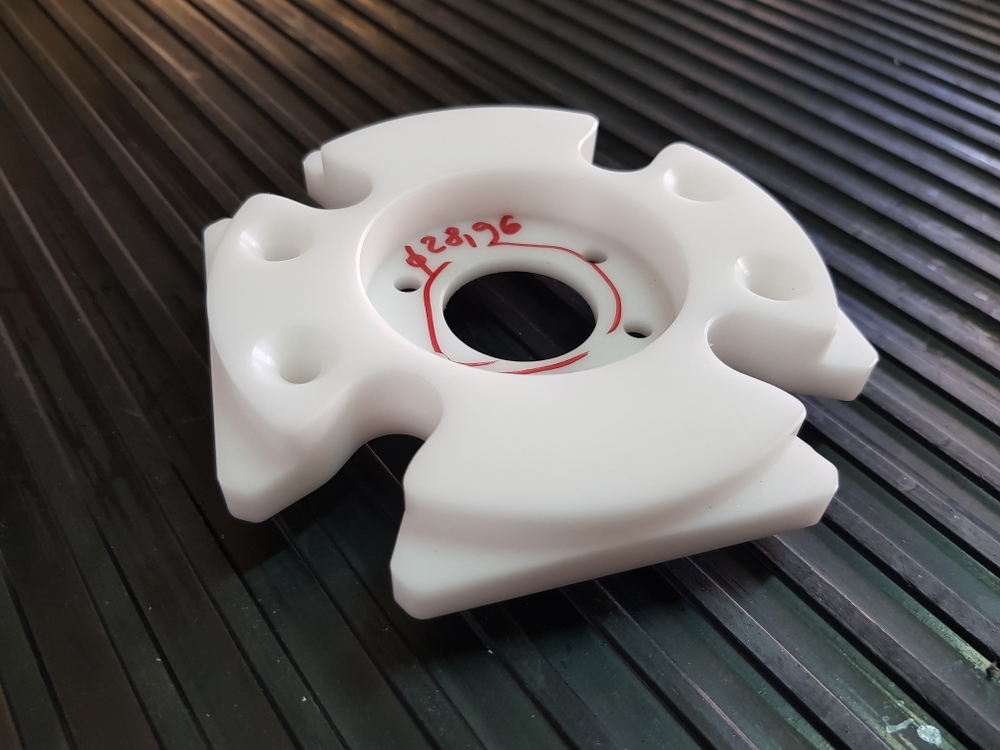

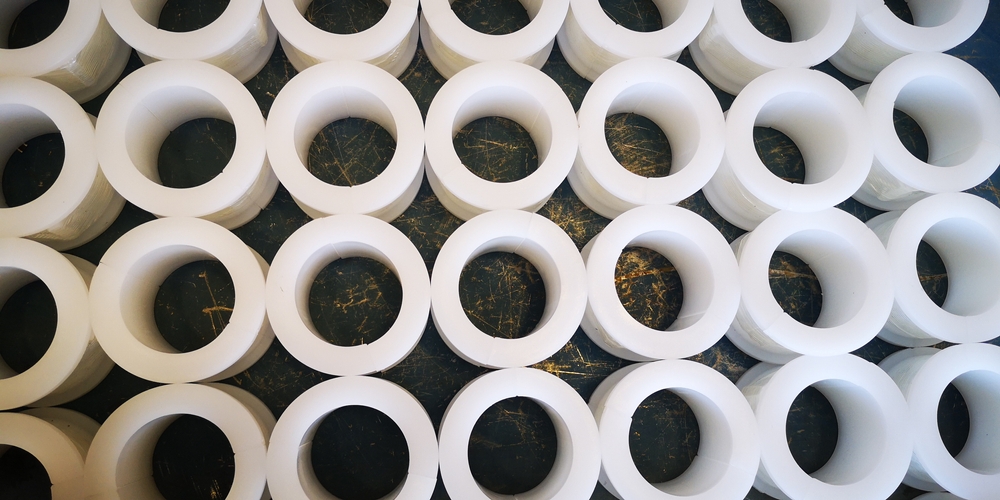

High-performance plastics of various materials in sheets, round rods, tubes, and other forms are Modulus Metal’s specialty. To satisfy varied project needs and standards, large quantities are on hand. Modern CNC machining services are part of our comprehensive range of industrial plastics supplies. Our selection of CNC machining tools consists of:

Saws, Mills, Lathes

Routers

Our ISO-certified machinery is built to manage specific tolerances, high order volumes, and short project turnaround times while ensuring quality control. Our machines, which specialize in huge components and parts, can perform a range of tasks, such as:

Milling, Turning, Drilling, Sanding, Forming, Grinding, Punching, Tooling, Welding

Modulus Metal specializes in work with high temperature and high strength materials, whether you need tailored parts, the fusing of complicated components, or finishing and polishing services.

TYPES OF MATERIALS CAN BE MACHINED BY MODULUS METAL

Modulus Metal is home to a variety of plastic materials. Below is a sample of our wide range of materials, which includes polymers for high temperatures and high resilience.

PEEK, Torlon®,Acetal, Delrin®, Nylon, Celazole®,PTFE ,Ultem® ,Noryl® ,Vespel®,Ertalyte®, Polysulfone, Lexan®, Techtron®, PPS, Radel®

Pros of Plastics Machining

There are no mold-related expenditures.

being able to produce plastic components with quick lead times

the capacity to produce in low numbers profitably

Can a design be tested before moving forward with tooling?

Wall parts that are thicker can be permitted.

Machined plastic parts can be used to create components that are too big to mold.

Plastics may be machined with little force.

Usually, plastics are machine-dried.

Swarf may be recycled to further the process of compounding.

Cons of Machining Plastic Materials

Only the most rigid plastics materials can be machined

Cost of block plastic material is rather expensive.

There may be a high scrap rate (in comparison to other plastics manufacturing techniques).

Having a large amount of swarf to remove might be challenging.

High CNC machine time costs