MODULUS METAL : Supplier and exporter of Sand Casting Foundry Products in Turkey

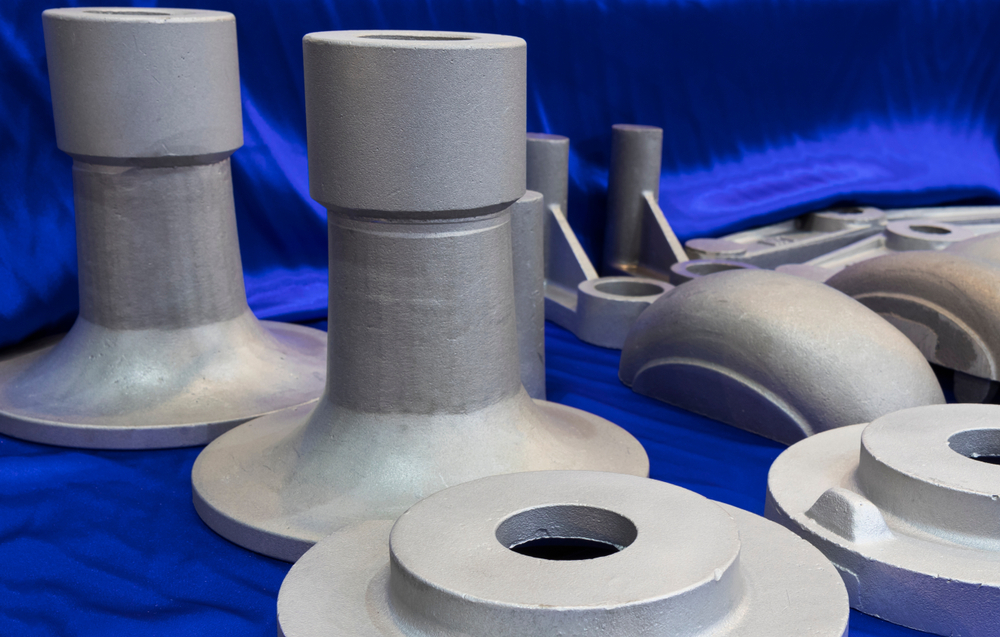

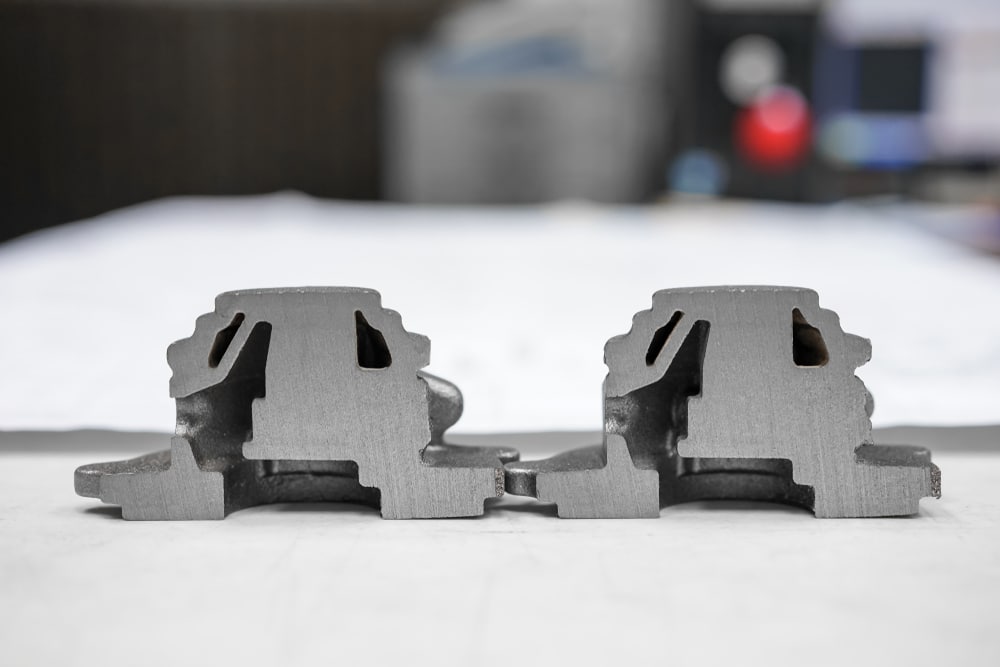

With a sand casting, you can create intricate shapes with many undercuts, holes, bosses, and protrusions since the mould can be constructed from several components. This implies that complex components with internal channels and gateways that are impossible to achieve using other techniques can be constructed fairly easily.

Tool prices can be relatively modest, and most tool adjustments are straightforward and cost-effective. Sand casting is a wonderful option for early production and prototyping since it allows for the possibility of design changes.

PROCESS NORMS, TOLERANCES, AND LIMITATIONS

Production rates: Before die casting becomes a viable alternative, components can be produced in economically feasible quantities of up to 1000–5000 per year. Sand casting, however, can continue to be a practical production option at more than 1,000,000 units annually for components that cannot be produced using other techniques, such as die casting.

For light alloys, the typical minimum wall thickness is 3 mm; for steel and other ferrous alloys, it is closer to 5 or 6 mm. The specific alloy will have a significant impact on this, thus it’s important to ask the foundry for recommendations.

Maximum wall thickness: Sections that are thicker than 100mm are possible

Draft angles: 1 to 5 degree draft angles must be used.

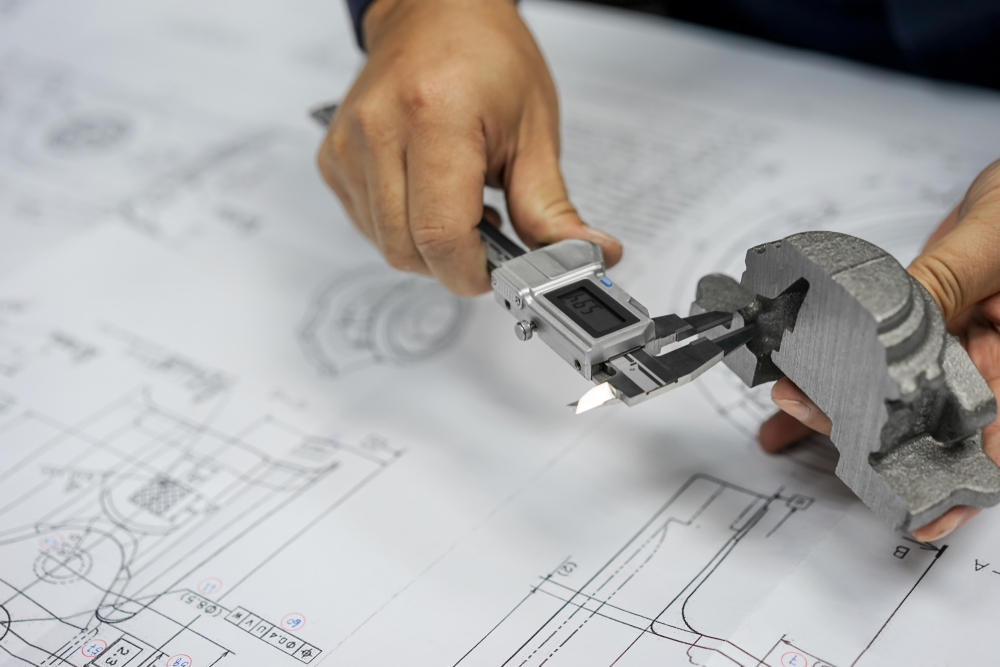

Linear tolerances that can be attained are +/- 0.4 to 0.5 mm, with a further 0.25 to 0.25 mm across mold parting lines and core joints.

Linear tolerances are typically +/- 1 mm, with an extra +/- 1 mm across mould parting lines and core joints.

Flatness: 0.1mm per 25mm is usual (excluding localised pitting)

Finishing: 3.2-25.0 Ra (Micrometers)

Typical machining tolerances are 0.5-1.6% or 1.5-6mm.

Size restrictions: Weight ranges from 20g to many hundreds of tones are possible.

WHAT IS THE LIFE TIME OF SAND CASTING TOOLING?

The choice of tooling material depends on the estimated overall production volume and likelihood of design change. Polyurethane board may be machined quite quickly and easily modified in terms of dimensions or features. Tooling life would probably be around 5000 units, but depending on how complicated the pattern is, it may be much higher.

Aluminum tooling would be the natural next step after polyurethane (PU) board since it offers relatively simple machining while being more durable than polyurethane, with tool life typically ranging from 50,000 to 100,000 units.

WHAT SAND CASTING TYPE IS BEST FOR YOU?

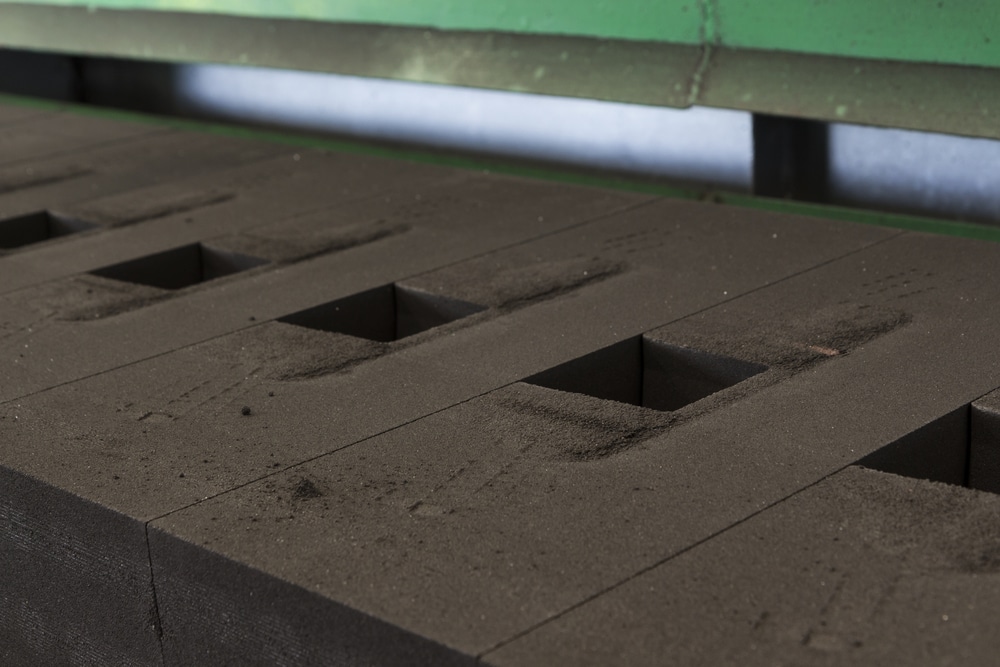

There are different steps in the sand casting process. The most popular method of sand casting is green sand casting since it is the least expensive, but the tolerances are the highest. On the other hand, dry sand (chemically bonded sand) casting provides more accurate castings with a superior surface polish, but because the mould must go through additional processing, it is invariably more expensive. This cost is all relevant to the complete project because more precise castings may require less machining and tolerance room, which would require fewer additional processes and result in a lower overall cost.

Mold cores are normally created using the dry sand molding technique or a variant of it, whether they are utilized with green or dry sand molding.

What do Dry Sand and Green Sand mean?

Molds for green sand casting are created from sand that has been joined with clay and water. Because the sand is easily recyclable and compressible, demolding and reprocessing are both less expensive and simpler. Casting in dry sand creates a stronger mold. By improving the bonding between the sand grains, either by the application of heat and a combination of heat-curing resin, gas injection – with chemically reacting resins, or simply by mixing air-curing resin with the sand, this strength is acquired. Due to the resin composition, less sand can normally be recovered than with green sand molding. Due to the molds’ enhanced strength, demoulding takes longer.A variety of mold types are used for dry sand casting, all of which depend on a chemical reaction, often the hardening of a resin mixed with the sand. The terms air set, boxless, cold-box, gas-set, no-bake, and chemically bonded sand moulding are also used to describe dry sand casting.

Related Tolerance standards

ISO 8062-1:2007 – Geometrical product specifications (GPS) — Dimensional and geometrical tolerances for moulded parts — Part 1: Vocabulary

ISO/TS 8062-2:2013 – Geometrical product specifications (GPS) — Dimensional and geometrical tolerances for moulded parts — Part 2: Rules

ISO 8062-3:2007 – Geometrical product specifications (GPS) — Dimensional and geometrical tolerances for moulded parts — Part 3: General dimensional and geometrical tolerances and machining allowances for castings

Limitations: Dry vs. Green Sand Casting

The size of the component is constrained by the size of the flask or mould box because green sand casting is done inside of one of these. It is wise to inquire about the standard size of the box since it is typically an established standard for your foundry. The number of components you can fit in a mould box will directly affect your production rate and cost since a single mould box may include numerous mould cavities that are poured using the same gating system.

Because the mold pattern is built to fit the component being cast rather than a fixed volume, as with green sand casting, dry sand casting is not constrained by box size.

Due of the decreased surface strength of the mold, green sand casting is not suitable for long, thin geometries like fins or deep pockets. This is due to the possibility that the pressure of the molten metal entering the mold will be sufficient to distort or wipe away specific characteristics.

The dimensional stability of dry sand casting, on the other hand, is significantly greater under the pressure of the molten metal as it enters the mould, allowing for the possibility of finer detail with long and thin sections.

Testing techniques

For finished steel castings, magnetic particle inspection as well as dye penetrant testing can be used to check for porosity and cracking.

To check castings for internal flaws and keep a permanent record of the investigation, X-rays are frequently used. Ultrasonic testing is another option, but it doesn’t produce a record that will last forever. Visual inspection makes it simple to spot faults and known deficiencies in certain components.

Related Testing Standards

ISO 4986:2010 Steel Castings – Magnetic Particle Inspection

ISO 4987:2010 Steel Castings – Liquid Penetrant Inspection

ISO 4992-1:2006 Steel castings — Ultrasonic examination — Part 1: Steel castings for general purposes

ISO 4992-2:2006 Steel castings — Ultrasonic examination — Part 2: Steel castings for highly stressed components

ISO 4993:2009 Steel and iron castings — Radiographic inspection

ISO 11971:2008 Steel and iron castings — Visual examination of surface quality

Sand castings are also frequently subjected to pressure testing because the molten metal must fill the mold only by gravity, which always results in some porosity in the casting. This can be reduced with a well-designed gate, runner, and feeder system; typically, your foundry will handle the design of this component.

HEAT TREATMENT

Once the sand mould has been separated from the casting, additional post-processing is necessary in addition to the obvious removal of the gates, runners, and feeders. Flash and any leftover witness marks are removed from gates, feeders, and runners by fettling, sanding, and grinding.

After that, castings normally require additional cleaning, which is typically accomplished using shot blasting. This eliminates discoloration and creates a surface finish that is consistent throughout the surface of the part. Any heat treatment that results in surface discoloration can be followed by doing this.

Heat treatment is frequently applied to both ferrous and non-ferrous castings for a variety of benefits, including as stress reduction, improved machinability, and greater strength.

Creating a sand casting of your design

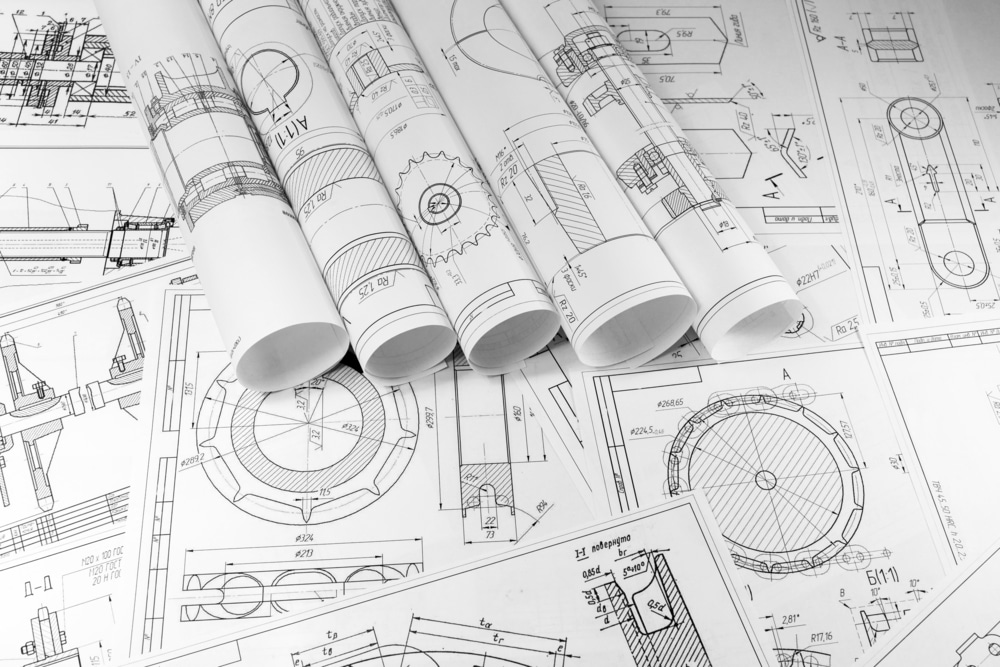

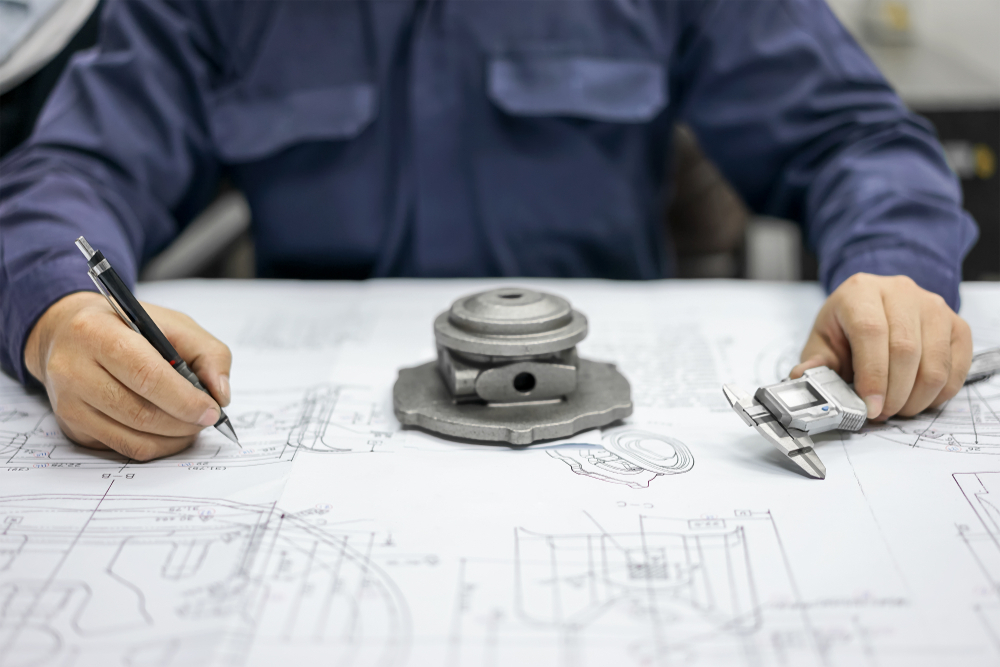

There is still some work involved in converting your desired completed geometry from a 3D model into castable geometry. the design of the runner, gate, and feeder system, as well as the incorporation of machining allowance, tolerancing allowance, and shrinkage allowance.

Process simulation for casting

Software for simulating the filling and cooling of the mould throughout the casting process is widely available. To help improve and prepare the geometry for casting, analysis of porosity areas, troublesome features, and predicted shrinkage can all be done.

Oversize Allowance

In order to account for shrinkage, your foundry will normally increase the component’s dimensions. Depending on the material, this increase can range from 5-20%. Although there is no requirement for your design here, it is important to keep in mind, particularly when speaking with your foundry.

Runners, Feeders, and Gates

Your foundry will use the geometry of your component to position the gates, runners, and feeding system first using their experience, and then optimization will be done using simulation and/or computation. In order to ensure that each mould cavity is filled evenly, your gate and runner system may need to transfer molten metal to many cavities.

SAND CASTING DRAWBACKS

Machine allowance and Surface Inclusions

It is understood that sand grains will be present as inclusions within the casting’s surface material. This is because as the molten metal runs through the mold, loose sand is taken up. If it is essential that the machined surface be fully free of sand grains, this must be taken into account while selecting the machining allowance.

Porosity

Even while the mold cavity appears to be full, it is actually not because liquid metal takes up more space than solid metal does. However, eventually the viscosity of the metal surpasses the drawing force of shrinkage. This is somewhat solved by utilizing feeders to allow the dragging of metal still in liquid form into the mould cavity. This indicates that the metal continues to cool and contract without the addition of new material, leading to porosity.

Even when the sand casting is well-designed for the procedure, porosity is more likely at the top because gas bubbles in the molten metal will try to climb up through the molten metal.

As a result, the design must contain appropriate amounts of porosity. Porosity need not necessarily affect a component’s functionality, especially if it only affects the surface and can be removed later through machining. Additionally, even if a surface is porous, a leak test can determine whether the overall sealing integrity is still enough for the design. However, further machining and treatment can cause pores to link, resulting in leakage even if a casting passes a leak test.

A casting can be resin impregnated if porosity is a problem but the design allows it. During this process, resin is often pumped under vacuum into the casting to fill the small pores as well as the surface.

Considerations for casting impregnation

-The completed component should be impregnated after machining. It has no effect on the finished size or appearance.

-The presence of resin can preclude a totally integrated weld when welding a casting.

-Pressure decay and leak testing may prove to be more expensive than 100% casting impregnation.

-Resin can be infused into any sand cast material.

Components that were never meant to be “leak tight” can likewise experience issues due to porosity. Problems can arise with powder coating in particular because the component “outgases” when the powder coat is baked or cured. Poor adherence of the powder coating is caused by trapped gasses that simply expand and push their way to the surface.

DESIGN GUIDANCE FOR SAND CASTING

Because sand casting is a very adaptable method that can produce highly complicated shapes and internal geometry, design guidance can be rather general.

The foundry should be involved in the finer design elements, but the earlier you can get guidance on how to optimize a design for sand casting, the better.

Radii Smooth, flowing contours make sense for the geometry because the procedure includes the flow of molten metal. This avoids turbulence during mould fill and a wide range of possible faults.

However, higher localized material thickness that results from increased Radii is also undesirable and can result in flaws when the material cools and shrinks.

Therefore, it is generally recommended to produce smooth corners with a Radii that is appropriate for the thickness of material being moulded on the mould surfaces and any cores.

Internal radii typically equal 1 to 1.25 times wall thickness

Wall thickness + Internal Radii = Typical External Radii

Therefore, it should go without saying that an external radius should be added in addition to an internal one to prevent a concentrated thick portion in the casting’s corner.

The radius may be determined from the thinnest wall section when several wall thicknesses are linked at a corner, but be ready to fine-tune this with your foundry.

Changes in Section or “Thickness”

Now you hear that everything should have a consistent wall thickness, but you also hear that you should include a draft angle—two suggestions that, in certain situations, seem to be at odds with one another. So let’s explain this.

Although it is often impractical to have walls of constant thickness, the idea is not to isolate thicker portions of the casting during cooling. The thicker piece will cool last, and if the entire area of metal has solidified before it, when it cools it cannot “feed” from the areas around it, which can result in flaws like porosity or ripping.

*Create your component with any thickness increments going uniformly in one direction.

As a result, it is OK to raise the wall thickness of your component as you move toward the “top” if it has a 3mm wall thickness at the bottom. By having the material “feed” from top to bottom, you may prevent porosity.

That is a greatly oversimplified illustration because actual components are far more complicated than that. Therefore, I advise speaking with your foundry about the direction of the sand casting within the sand mould before working on constructing the walls to enable proper feeding.

When drastic thickness changes are needed for design or production reasons, utilize a taper to achieve the desired thickness change instead.

Minimum Taper: 1:4 if wall thickness is doubled.

It is important to explore the possibilities for thickness modifications with your foundry in light of your material.

Use of ribs or webs is a clever technique for boosting localized stiffness in a sand casting; these can enhance stiffness greatly when compared to just increasing wall thickness. Ribs and webs that you design in must adhere to the same minimum wall thickness and radius requirements.

Draft Angles

The sole purpose of the draft angles is to make it possible to remove the sand mold from the pattern. A typical draft on both internal and external surfaces should be around 2 degrees; 1 degree is highly likely. But another important factor in defining the angle that can be used is the length or depth of a feature; the longer the feature, the steeper the angle needed.

A sharper draft angle of 3-5 degrees will greatly aid in manufacturing consistent sand moulds, even if it is not design necessary.

The precise sand casting method your foundry employs will consequently have a considerable impact on the draft angles that can be achieved. Dry sand casting allows for the use of tiny draft angles over significant depths since the moulds are more stronger than those used in green sand moulding.

Junctions

Areas of natural localized thickness, such as an X-Junction or T-Junction, are called junctions. Consequently, you should use caution when creating features that lead to these “Junctions”. Internal elements like ribs and webs or outward protrusions like fins or brackets are common examples of junctions.

When external and interior geometry that are functionally unrelated are positioned on the same portion of the casting wall, less visible connections may become apparent. For instance, an internal rib may share the same casting wall space as a boss or lug on the casting’s exterior.

Moving these functionally unrelated features farther apart on the casting’s wall would minimize or even completely eliminate localized thickening.

Parting Lines

Once more, your foundry will be in the best position to advise on a good parting line because of how its location will affect the design-related tasks it will handle.

Even when theoretically creating, it’s a good idea to be mindful of possible separation lines because they might place many restrictions on your design.

When determining a separation line, keep the following in mind:

*It should be at a sand casting’s edges or corners rather than along flat surfaces.

*It should be as low as feasible in the sand casting for less dense materials (such as aluminum alloys).

*It need to be situated around halfway up the sand casting in cases where the material is more dense (such as iron).

SUMMARY

Sand casting is a very flexible process, and there are lots of things that can be optimized in the production process to attain the tolerances, finishes, and price points you want. Early consideration of the manufacturing process, as always, will result in a design that is fundamentally more cost-effective in terms of both the price per piece of the product and the cost of product creation. Hopefully, this post has given you some pointers on things to watch out for during design as well as some words that will help you communicate with your foundry much more effectively.

How to find suitable sand casting foundry for your requirements in Turkey?

There are numerous foundries in Turkey that specialize in both airset and green sand casting (and a mixture of everything in between). If you’re looking for a manufacturer for your project, head over to the Supplier Search via Google or supplier search websites, where you can look for a manufacturer who offers the mix of procedures you need to optimize and streamline your supply chain.