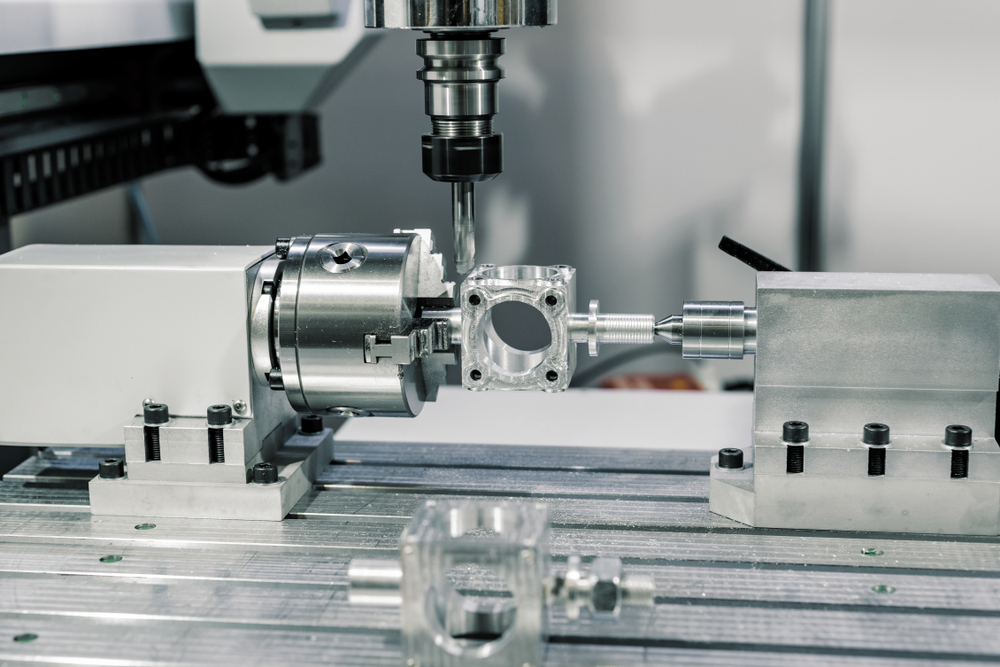

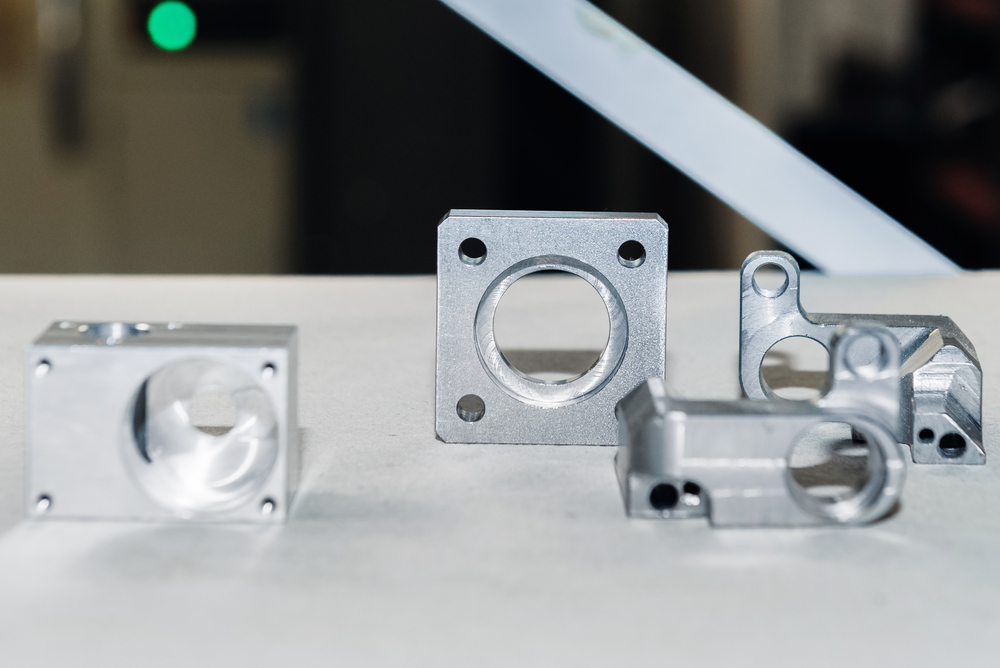

For many parts in many sectors, aluminum offers good machinability, durability, low weight, and low cost.

Aluminum and aluminum alloys are widely chosen by designers and engineers for CNC-machined and CNC-milled items. Senses well. This versatile metal has demonstrated benefits in:

Outstanding machinability

High strength

Hardness

Resistance to corrosion and heat

Conductivity of electricity

Low weight

Low price

General adaptability

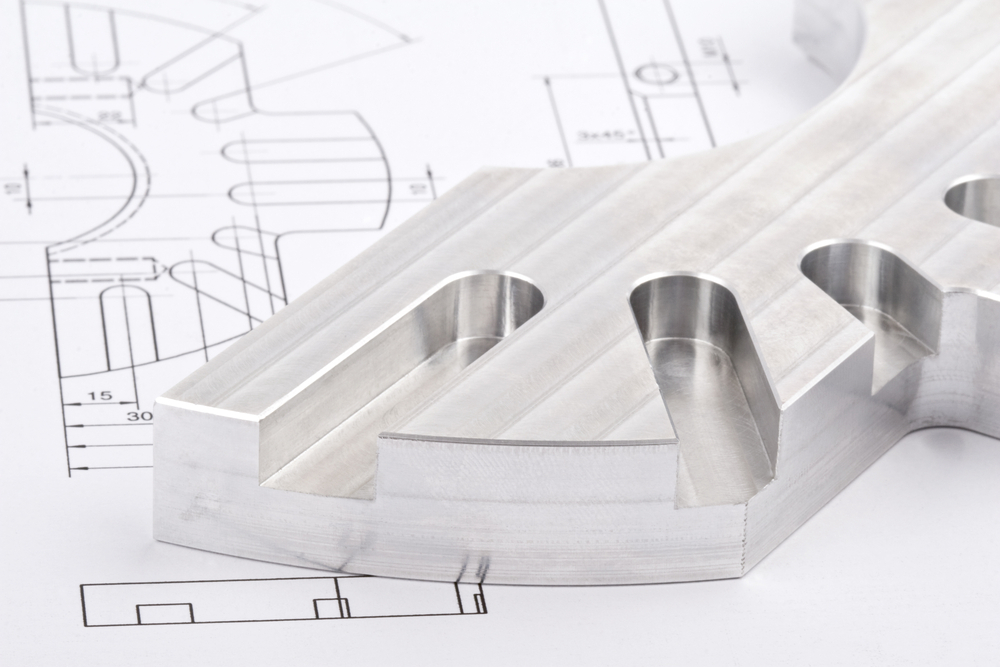

MACHINING OF ALUMINUM ALLOYS

Modulus Metal has a large selection of aluminum alloys in its assortment of production materials. Aluminum 6061 and 7075 are two of those alloys that are particularly well-suited as material choices for CNC machining, whether milling or turning.

The benefits of aluminum 6061 include its cost, adaptability, great resistance to corrosion, and superior aesthetic after anodizing.

The benefits of aluminum 7075 include its high strength, hardness, lightweight weight, resistance to corrosion, and high heat tolerance.

Comparison of 6061 and 7075 Aluminum Alloys:

| 7075 Aluminum | 6061 Aluminum | |

| % Aluminum (Al) | 90.0% Al | 97.9% Al |

| % Zinc (Zn) | 5.6% Zn | — |

| % Magnesium (Mg) | 2.5% Mg | 1.0% Mg |

| % Chromium (Cr) | 0.23% Cr | 0.2% Cr |

| % Copper (Cu) | 1.6% Cu | 0.28% Cu |

| % Silicon (Si) | — | 0.6% Si |

| Alloy | Temper | Ultimate Tensile Strength | Elongation | Hardness |

| Aluminum 6061 | T651 | 310 MPa | 13% | 95 HRB |

| Aluminum 7075 | T651 | 560 MPa | 10% | 150 HRB |

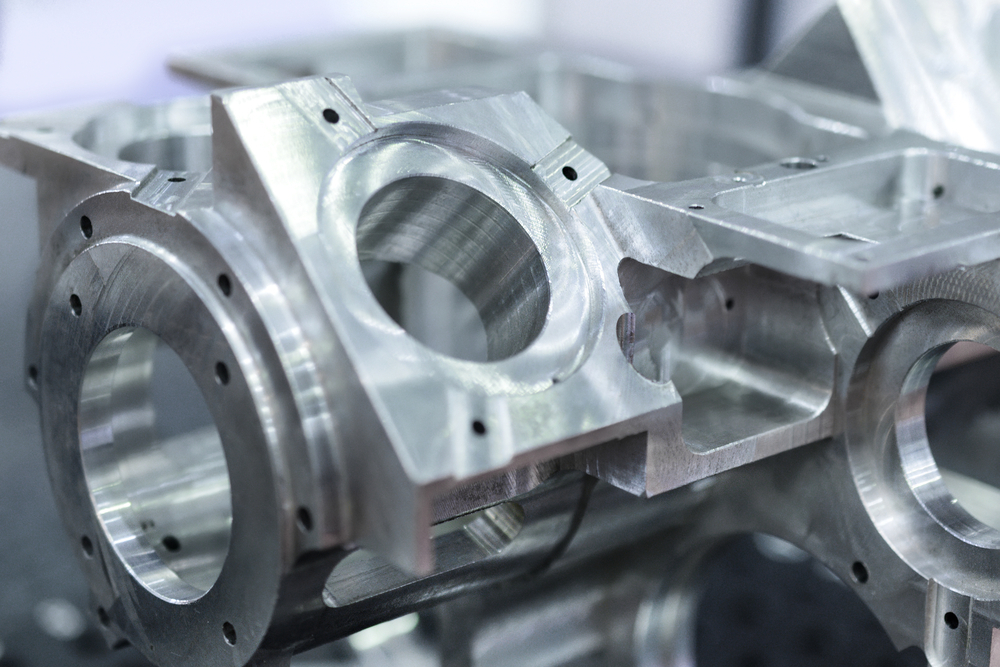

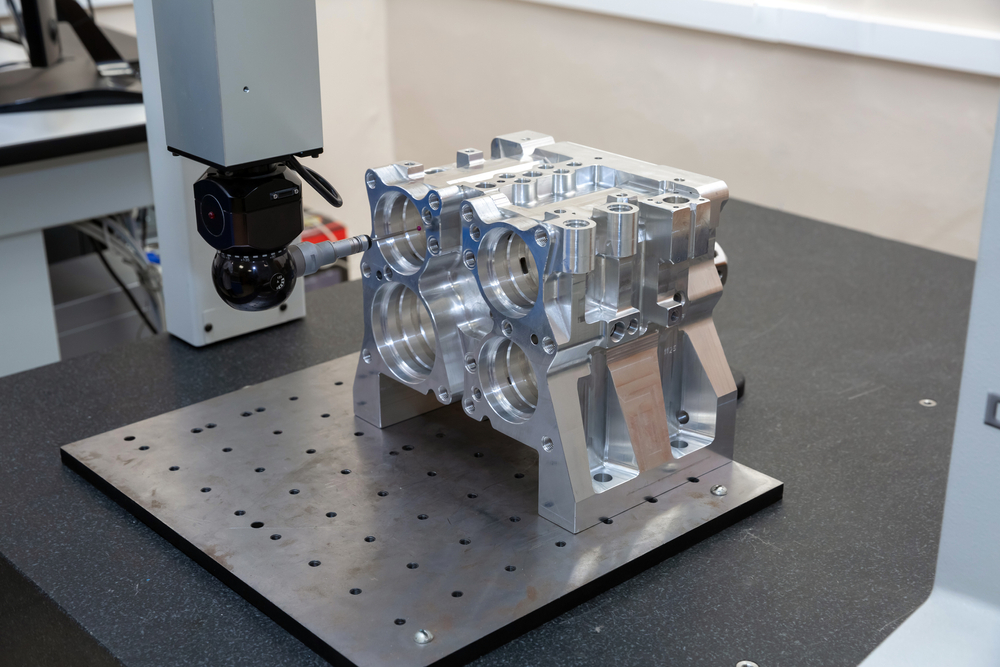

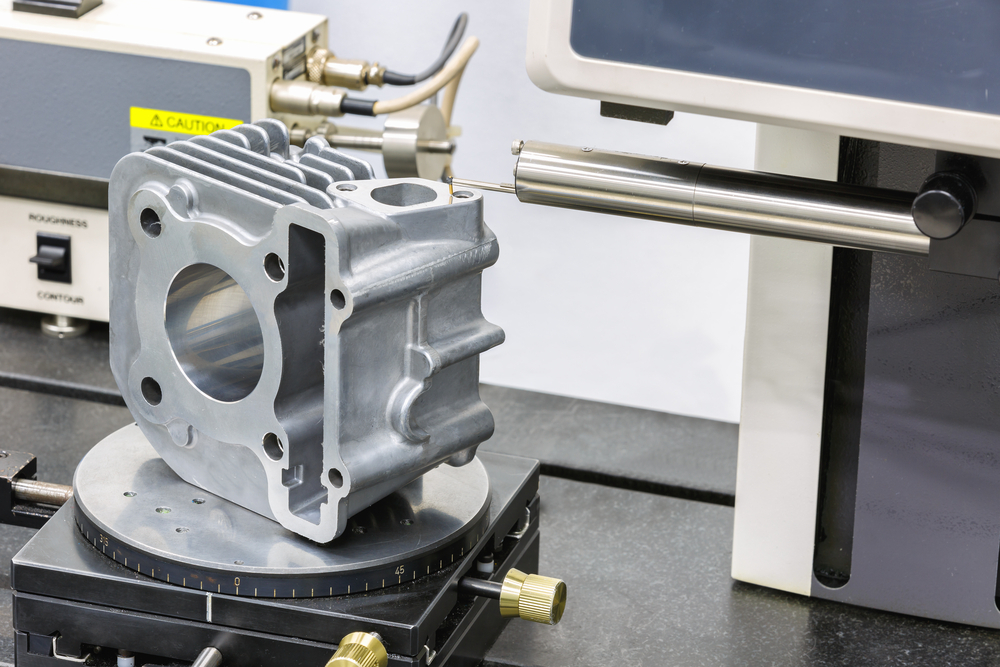

Aluminum Applications Using Machining

Aluminum components are widely used in a variety of industries, particularly the automotive, aerospace, mechanical, and consumer and computer electronics. Automotive components (light-weighting provides high strength-to-weight ratio). Housing, brackets, and other aerospace-related items that need to handle strong loads but weigh little. Fixtures, calipers, and numerous other components for industrial machinery Electronics for consumer and computer use include enclosures, panels, consoles, knobs, and other components.

While other aluminum alloys may offer better formability and weldability, 7075 aluminum performs well in high-stress situations where strength is crucial. One of the strongest aluminum alloys on the market, 7075 aluminum is frequently referred to as “aircraft grade.” It is frequently utilized in spacecraft, missiles, airplanes, and other defense-related applications. Additionally, it can be found in structural materials, military applications, and other areas that experience heavy wear.

With regard to structural materials, welded assemblies, pipes, fasteners, electronic components, and more, 6061 aluminum is used in a variety of all-purpose applications due to its adaptability, workability, strength, resistance to corrosion, and joinability. It is frequently employed in a variety of applications and industries.

Typically, 6061 aluminum is used in:

Sailboats, yachts, marine hardware, and shipbuilding

Automobiles – the bodywork, wheels, brakes, and hydraulic pistons of trucks and buses

Airplane components and structures

Railroad car parts

Awnings for furniture, moldings, and appliance fittings

Cans of food and beverages

Aluminum bar, aluminum tube, and aluminum plate all come in 6061 aluminum.

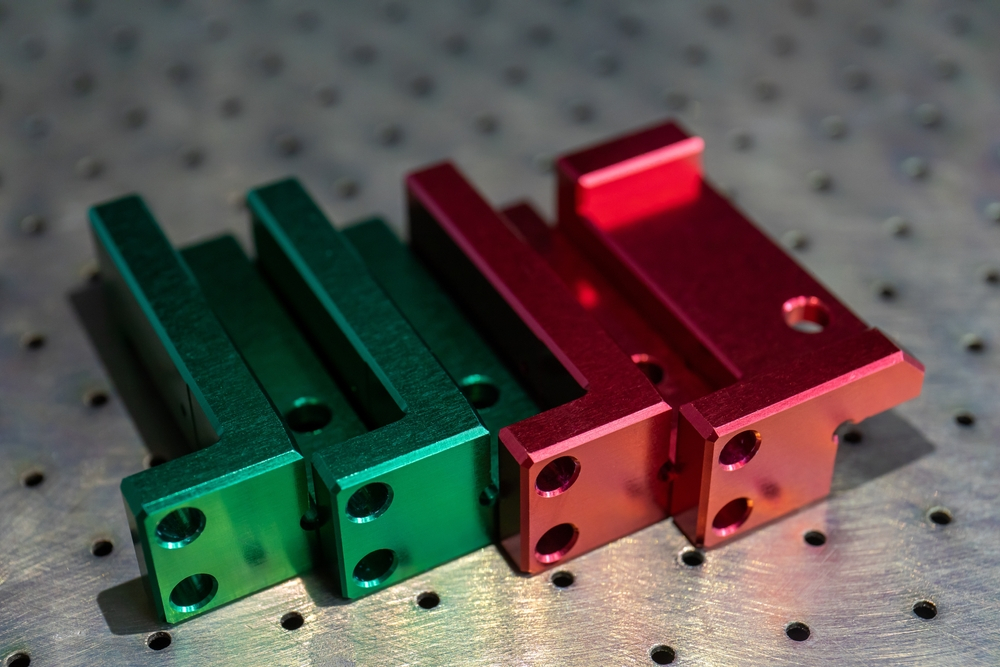

Options for Anodizing CNC Machined Aluminum Parts

One of the most popular methods for enhancing the appearance of metal items and providing effective corrosion protection is anodizing. Modulus Metal offers forms of aluminum anodizings.

When to use 6061

The project requires a lot of welding and a lot of machining, and cost is a major consideration.

When to use 7075:

The part needs to be strong and have high strength and low weight because it will be exposed to a lot of friction and heat. Cost is less of an issue.