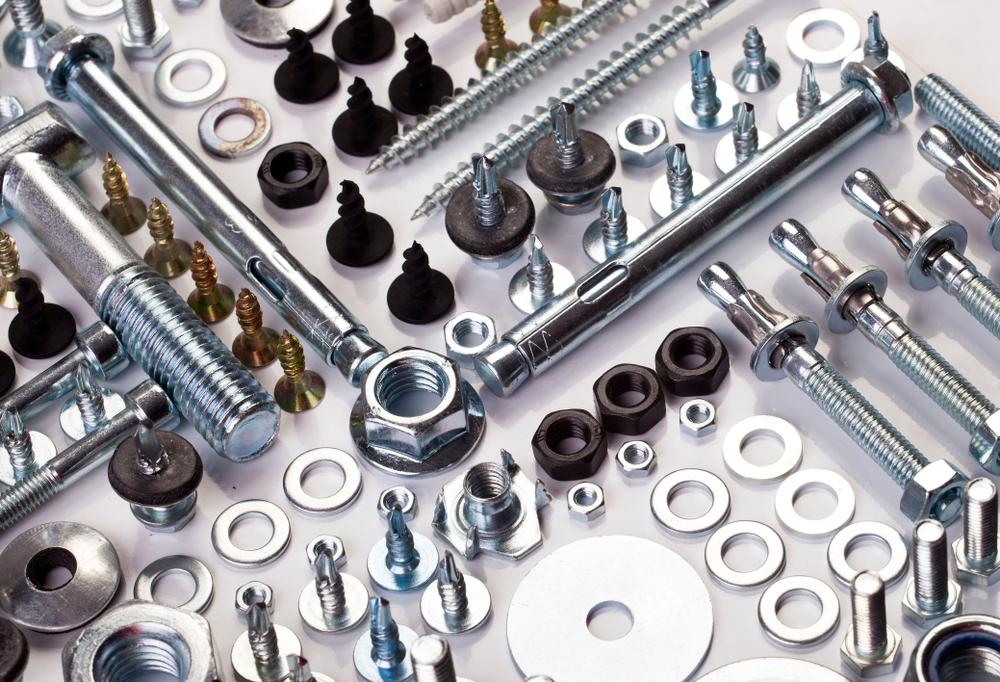

FASTENERS

Type of Fasteners

Bolts

Buckles

Bushings

Caps & Ends

Clamps

Clasps

Clevises

Clips

Cold Headed

Connectors

Dowels & Pins

Hose Couplings

Locknuts

Nails

Nuts

Rivets

Screws

Shackles

Shaft Couplings

Shafts

Spline Shafts

Studs

Washers

Materials

Alloy Steel

Aluminum

Brass

Copper

Exotic Metals

High Carbon Steel

Low Carbon Steel

Silicone Bronze

Stainless Steel

Bolt Types

Anchor

Anti-Rotation

Carriage

Clevis

Closet

Countersunk

Custom

Elevator

Eye Bent

Hook Bent

J Bent

Lag

Shoulder

Special

T-Handle

T-Head or T-Slot

Toggle

U Bent

Bolt and Screw Head Types

Binding

Button

Fillister

Flat

Flat Undercut

Headless

Hexagon

Indented Hexagon

One-Way

Oval

Pan

Phillips

Round

Shoulder

Socket

Square Shoulder

Trimmed Hex

Truss

Thread Types

American Corps of Mechanical Engineering (ACME)

Drive Screws

Drywall

Machine

Particle Board

Self-Drilling

Self-Drilling Drive Screws

Tri-lobular

Type 17

Type 23

Type 25

Type A

Type AB

Type B

Type F

Unified Coarse (UNC)

Unified Fine (UNF)

Bolt and Screw Drive Types

Combination

Hex/Hexagonal

Phillips

Six Lobe

Slotted

Socket

Square

Tamper Resistant

Torx

Nut Types

2-Way

Anchor

Automation

Cap

Castle

Center Lock

Conical

Coupling

DIN 980V

DIN 985

Eye

Finished Hex

Flex Lock

Heavy Hex

Hex Flange

Hex Jam

Keps

Nylon Insert

Nylon Patch

Nylon Pellet

Semi-Finished Hex

Serrated Hex Flange

Slotted Hex

Square

Thumb

Top Lock

Weld

Wing

Fitting and Nipple Types

Caps

Couplings

Elbows

Floor Flanges

Nipples

Reducing Couplings

Tees

Pin Types

Clevis

Cotter

Dowel

Ejector

Hitch

Locating

Self-Locking

Spring

Tapered

Rivet Types

Blind

Closed End

Hollow

Internally Threaded

Multigrip

Outside Prong

Pronged

Rod

Semi-Tubular

Slotted

Solid

Split

Threaded

Tubular

Washer Types

Arc

Belleville

Bevel

Conical

Dock

External

Fender

Fiber

Finishing

Flat Machine

Grommets

Hexagon

Hi-Collar

Insulating

Internal

Load-Measuring

Lock

Metric

Neoprene

Retaining Rings

Screw

Sealing

Split

Wave

Finish

Black Oxide

Everlube

Exotic Finishes

Mechanical Zinc

Organic

Powder Metal

Restriction of Hazardous Substances (RoHS) Compliant

Tin Plating

Zinc

Zinc Iron

Zinc Nickel

Zinc Phosphate

Additional Services

Anodizing

Assembly

Chamfering

Computer-Aided Design (CAD)

Computer-Aided Manufacturing (CAM) Programming

Electro-plating

Grinding

Heat Treating

Looping

Machining

Magnafluxing

Painting

Passivating

Powder Coating

Riveting

Swaging

Tapping

Tube Forming

Welding